3

OPERATION AND MAINTENANCE

The Grease Gun is designed to operate at 90 psi. Lower

pressure will reduce the performance of the tool, while

higher pressure will damage the internal components of

the tool.

CAUTION

CAUTION

Do not press the plunger release valve while

loading.

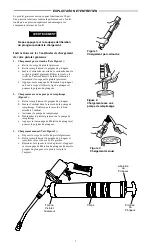

Instructions for the 3 Ways to Load your

Grease Gun

1. Cartridge Loading (Figure 1):

a. Remove the canister from the Grease Gun.

b. Draw the plunger handle back completely.

c. Insert the open end of the cartridge into the canister

of the grease gun. Remove the seal or pull--tab from

the other end of the tube and tightly re--attach the

canister to the Grease Gun.

d. Press the plunger release valve at the bottom of the

canister and release the plunger rod and push down

the plunger handle.

2. Loading with a Filler Pump (Figure 2):

a. Draw back the plunger handle completely.

b. Insert plug into the filler pump socket. Make sure

the socket is securely fastened to the plug.

c. Operate the filler pump.

d. Disconnect the grease gun from the filler pump.

e. Press the plunger release valve and push down the

plunger handle.

3. Hand Loading (Figure 3):

a. Remove canister from grease gun head.

b. Draw back the plunger handle completely and load

grease into empty canister.

c. Re--attach the canister to the gun head and press the

plunger release valve. Push down the plunger

handle and begin using.

Fig. 1:

Cartridge Loading

Fig. 2:

Loading with Filler Pump

Fig. 3:

Hand Loading

Grease

Gun

Head

Canister

Plunger

Release

Lever

Plunger

Handle