... kg

New Style

(Dwg. MHP3325)

INSPECTION

n

Frequent Inspection

For hoists in continuous service, frequent inspection should be made by operators

at the beginning of each shift. In addition, visual inspections should be conducted

during regular operation for any damage or evidence of malfunction.

1.

OPERATION. Check for visual signs or abnormal noises (grinding etc.) which

could indicate a potential problem. Check load chain feed through the hoist. If

chain binds or jumps, clean and lubricate. If problem persists, replace the chain.

Do not operate the hoist until all problems have been corrected.

2.

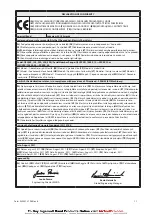

HOOKS. Check for wear or damage, increased throat width (refer to

Dwg. MHP0040 on page 8 and refer to Table 3 ‘Throat width and Discard

width’ on page 8), bent shank or twisting of hook (refer to

Dwg. MHP0111 on page 8 ). Refer to the latest edition of ASME B30.10

“HOOKS” for additional information. Check hook support bearings for

lubrication or damage. Check hooks swivel easily and smoothly.

Throat

Width

A

(Dwg. MHP0040)

Table 3: Throat width and Discard width

Hoist Model

Throat Width *

Discard Width

in

mm

in

mm

QCH50

1.1

28

1.26

32

QCH100

1.34

34

1.54

39

QCH200/300/500

1.65

42

1.85

47

(Dwg. MHP0111)

* Dimensions are based on the throat width opening.

3.

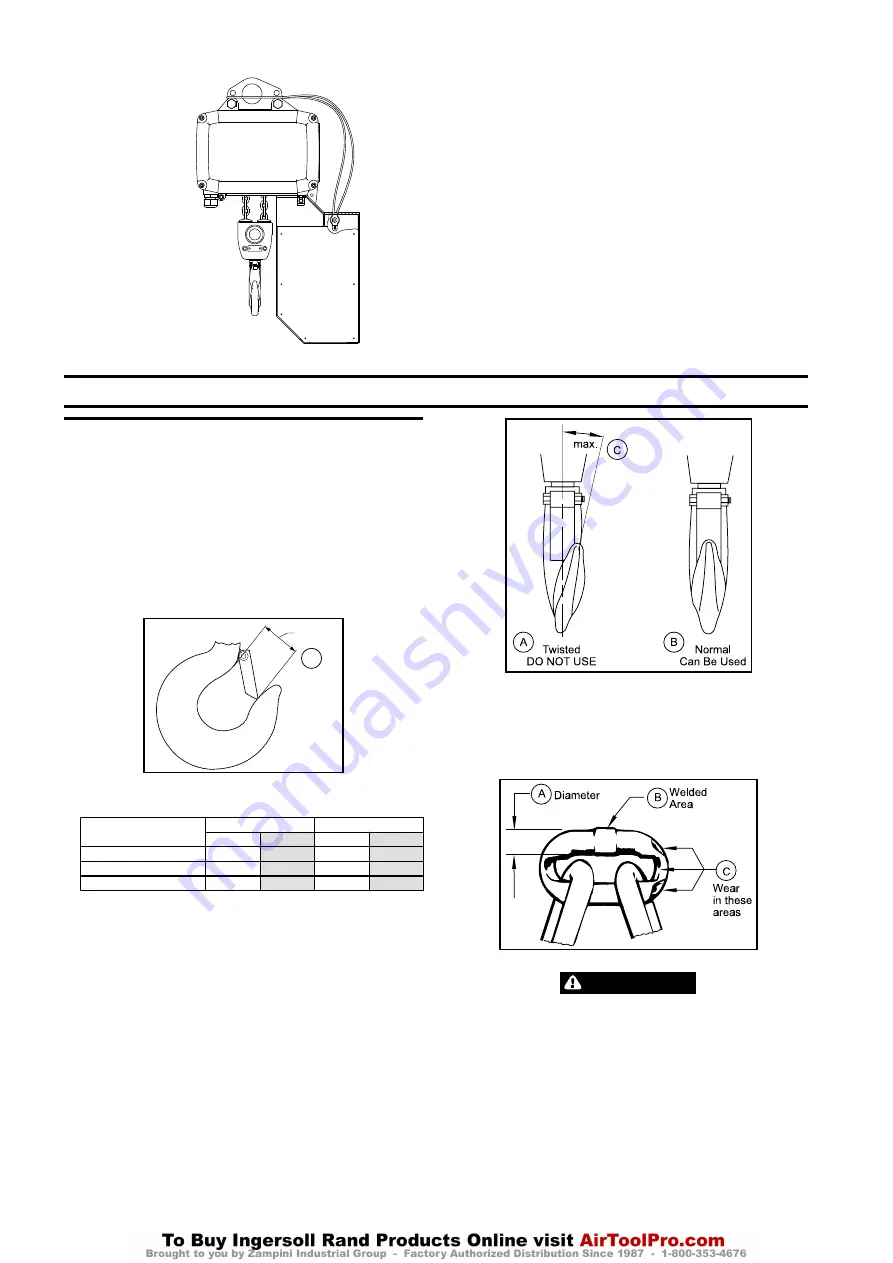

CHAIN. Examine each link for bending, cracks in weld areas or shoulders, traverse

nicks and gouges, weld splatter, corrosion pits, striation (minute parallel lines)

and chain wear, including bearing surfaces between chain links (refer to

Dwg. MHP0102 on page 8 ). Replace a chain that fails any of the inspections.

Check chain lubrication and lubricate if necessary.

(Dwg. MHP0102)

CAUTION

•

Excessive wear or stretching may not be apparent from visual observation.

At any indication of wear or stretching inspect the chain in accordance with

instructions in “Periodic Inspection”. A worn load chain may cause the load

sheave to wear rapidly. Inspect the load sheave and replace if damaged or

worn.

4.

CONTROLS. During operation of hoist, verify response to pendant is quick and

smooth. Ensure that the controls return to neutral when released. If hoist

responds slowly or movement is unsatisfactory, do not operate hoist until all

problems have been corrected.

5.

ELECTRICAL SYSTEM. Visually inspect all connections and components for

indication of damage or loose connections. Shut off and disconnect power prior

to removing inspection covers, repairing any damage or tightening connections.

6.

HOOK LATCH. Make sure the hook latch is present and operating. Replace if

necessary.

8

Form 04585147 Edition 6

Summary of Contents for QCH Series

Page 12: ...www ingersollrandproducts com...