04576070_ed2

5

Maintenance

WARNING

Always wear eye protection when operating or performing maintenance on this tool.

Always turn off the air supply and disconnect the air supply hose before installing, removing or adjusting any accessory on this tool or

before performing any maintenance on this tool.

Whenever one of the Sanders is disassembled for overhaul or

replacement of parts, lubricate as follows:

Always wipe the Vanes (21) with a light film of oil before inserting

them into the vane slots.

•

Inject 0.5 to 1.0 cc of

Ingersoll Rand No.10

Oil into the air Inlet

Bushing (1) after assembly.

•

Disassembly

Lubrication

General Instructions

1. Do not disassemble the tool any further than necessary to replace

or repair damaged parts.

2. Do not press any needle bearing from a part unless you have a

new needle bearing on hand for installation. Needle bearings are

always damaged during the removal process.

3. When grasping a tool or part in a vise, always use leather–covered

or copper–covered vise jaws to protect the surface of the part

or tool and help prevent distortion. This is particularly true of

threaded members and housings.

4. Do not remove any part which is a press fit in or on a

subassembly unless the removal of that part is necessary for

repairs or replacement.

Removal of the Sanding Pad

1. Place a 1/8” hex wrench in the set screw in the center of the

Pad (27).

2. Holding the set screw in place, unscrew the Pad from the set

screw.

3. Remove the spacer from the set screw.

4. With the Pad removed, lubricate the counterbalance needle

bearing by injecting one or two strokes of

Ingersoll Rand No. 68

Grease into the threaded end of the Spindle.

Disassembly of the Base Adapter

1. Remove the Cold Air Channel from the tool by removing the

Spring Clamp (33).

2. Remove the Shroud to expose two Roll Pins (41).

3. Using pliers or a vise, remove the Roll Pins.

4. The Housing Adapter (32) will slip out of the Sander face,

exposing the Motor Lock Ring (24).

Disassembly of the Spindle

1. Remove the Sanding Pad and Base Adapter.

2. Remove the Retaining Ring (26).

3. Remove the Spindle Assembly (25) including bearing.

NOTICE

Do not attempt to remove the bearing from the Spindle.

4. Remove the Motor Lock Ring (22) and pull the motor and

Seal (17) from the Housing (1).

5. Remove the Retaining Ring (13).

6. Using special brass blocks to fit around the outside diameter of

the Cylinder (16), clamp around the Cylinder and press the shaft

of the Counterbalance (24) through the Bearing (14) and Rear End

Plate (15).

7. Remove the Vanes (19), Rotor (18) and Key (23).

8. Remove the Front End Plate (20) and Bearing (14).

Disassembly of the Throttle

1. Remove the Inlet Adapter (9). This will release the Spring (8) and

Tip Valve (7).

NOTICE

Do not remove the Seat (6) unless it has been damaged.

2. Remove the Muffler (11), releasing the Muffler Tube (10).

3. To remove the Valve Stem (2), remove the Roll Pin (4) and

Lever (3).

Assembly

General Instructions

1. Always press on the

inner

ring of a ball–type bearing when

installing the bearing on a shaft.

2. Always press on the

outer

ring of a ball–type bearing when

pressing the bearing into a bearing recess.

3. Whenever grasping a tool or part in a vise, always use

leather–covered or copper–covered vise jaws. Take extra care not

to damage threads or distort housings.

4. Except for bearings, always clean every part and wipe every part

with a thin film of oil before installation.

5. Check every bearing for roughness. If an open bearing must be

cleaned, wash it thoroughly in clean solution and dry with a clean

cloth. Sealed or shielded bearings should not be cleaned. Work

grease into every open bearing before installation.

6. Apply a film of O-ring lubricant to every O-ring before installation.

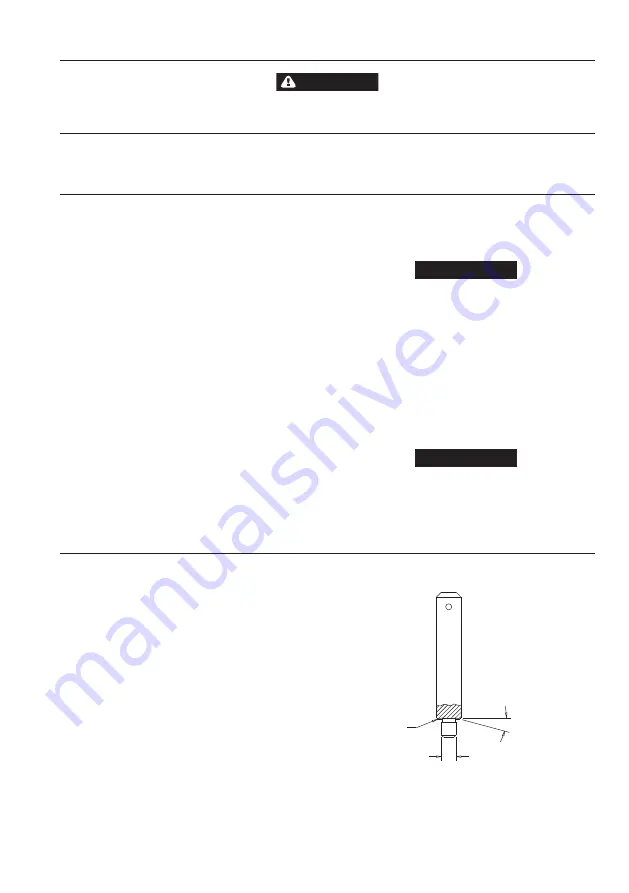

7. Unless otherwise noted, always press on the stamped end of a

needle bearing when installing a needle bearing into a recess.

Use a bearing inserting tool similar to the one shown in

Dwg. TPD786.

Needle Bearing inserting Tool

Shoulder to

Regulate Depth

Pilot to fit I.D. of Bearing.

Length of Pilot to be

approximately 1/8” less than

length of Bearing

15°

Dwg. TPD-786.