http://air.ingersollrand.com

1

OPeRATIOn AnD MAInTenAnCe MAnUAL

InSTALLATIOn / HAnDLInG

60Hz

UP6 5

UP6 7

UP6 10

UP6 15c

COMPReSSOR

125

150

210

125

150

210

125

150

210

125

150

210

Operating pres-

sure PSIG (bar)

125

(.)

150

(10.)

--

125

(.)

150

(10.)

210

(1.5)

125

(.)

150

(10.)

210

(1.5)

125

(.)

150

(10.)

210

(1.5)

Factory set reload

pressure PSIG (bar)

110

(.5)

10

(.)

--

110

(.5)

10

(.)

10

(12.1)

110

(.5)

10

(.)

10

(12.1)

110

(.5)

10

(.)

10

(12.1)

Flow rate CFM

(m

/MIN)

1.5

(0.52)

1.0

(0.5)

--

2.0

(0.)

25.0

(0.1)

1.5

(0.50)

.0

(1.0)

(0.)

2.0

(0.)

55.0

(1.55)

50.0

(1.2)

.0

(1.0)

Airend discharge

temperature trip

point.

22°F (10°C)

Ambient operating

temperature

(min.)

→

(max.)

°F (+2°C)

→

105°F (+0°C)

MOTOR

Motor enclosure

ODP

TEFC

ODP

TEFC

ODP

TEFC

ODP

TEFC

Nominal power

5HP

.5HP

10HP

15HP

Speed

500 RPM

Insulation class

F

GeneRAL DATA

Residual coolant

content

ppm ( mg/m

)

Separator vessel

capacity

0. gallons ( Litres)

Coolant capacity

1.2 gallons (.5 Litres)

Sound pressure

level to

CAGI-PNEUROP

5 dB(A)

5 dB(A)

dB(A)

dB(A)

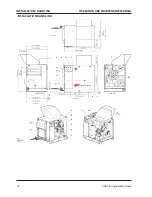

Weight-base

mount unit

25kg (50lb)

Weight-0 gallon

Receiver mounted

20kg (25lb)

Weight-120 gallon

Receiver mounted

kg (0lb)

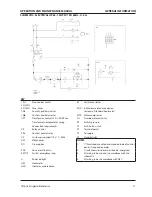

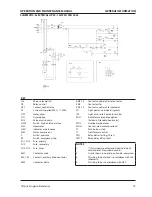

CAUTIOn

20/0 Dual voltage machines are fitted with a decal to advise the correct voltage as connected from the factory.

There is a decal fitted to the starter door describing the procedure to change the connections for the alternative

voltage.

Rewiring should only be effected by a competent Electrician.