16

TAM7-SF-2E-EN

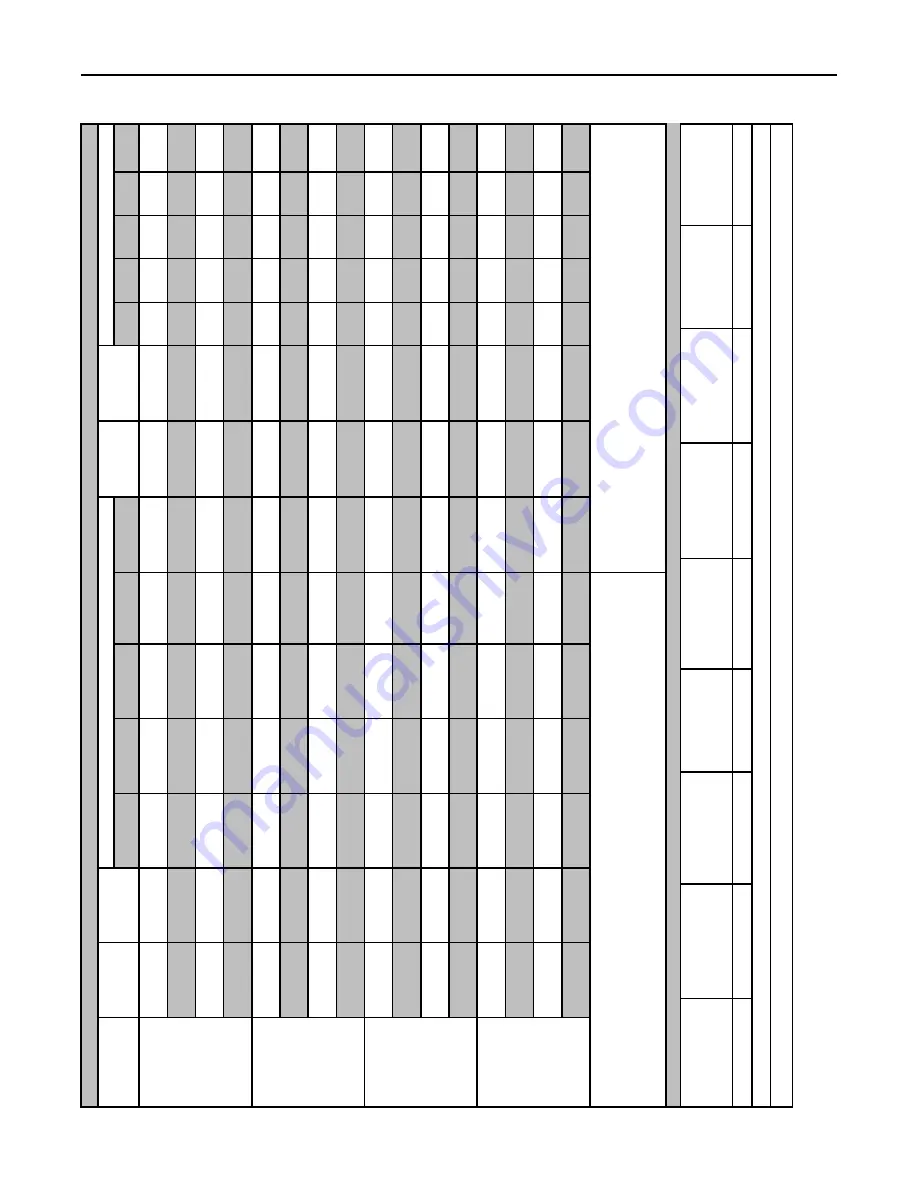

TAM7A0C48

AIRFLOW

PERFORMANCE

CONSTANT

CFM

MODE

/

CONSTANT

TORQUE

MODE

OUTDOOR

MUL

TIPLIER

(T

ONS)

COOLING

AIRFLOW

SET

TING

AIRFLOW

POWER

EXTERNAL

ST

A

TIC

PRESSURE

(Constant

CFM

/

Constant

T

orque)

HEA

TING

AIRFLOW

SET

TING

AIRFLOW

POWER

EXTERNAL

ST

A

TIC

PRESSURE

0.1

0.3

0.5

0.7

0.9

0.1

0.3

0.5

0.7

0.9

3

tons

330

CFM/ton

CFM

W

atts

1101

/

1127

92

/

117

1017

/

1020

143

/

143

1006

/

786

232

/

173

886

/

622

195

/

137

994

/

654

270

/

174

380

CFM/ton

CFM

W

atts

1150

128

1155

184

1154

237

1150

286

1141

330

350

CFM/ton

CFM

W

atts

1067

/1180

106

/

132

1073

/

1078

158

/

160

1065

/

859

252

/

192

1065

/

859

252

/

192

1053

/

738

292

/

194

400

CFM/ton

CFM

W

atts

1204

145

1210

203

1210

259

1207

310

1199

356

370

CFM/ton

CFM

W

atts

1122

/

1233

120

/

149

1129

/

1136

175

/

177

1122

/

929

274

/

212

1208

/

1029

309

/

244

1112

/

816

315

/

215

420

CFM/ton

CFM

W

atts

1259

162

1266

224

1267

282

1264

335

1258

384

390

CFM/ton

CFM

W

atts

1177

/

1287

136

/

167

1185

/

1194

194

/

196

1180

/

996

297

/

233

1353

/

1190

377

/

305

1170

/

890

341

/

238

440

CFM/ton

CFM

W

atts

1314

182

1322

246

1324

307

1322

363

1316

413

3.5

tons

330

CFM/ton

CFM

W

atts

1164

/

1274

132

/

162

1171

/

1179

189

/

191

1165

/

980

291

/

227

1031

/

817

240

/

181

1156

/

872

334

/

232

380

CFM/ton

CFM

W

atts

1323

185

1331

250

1333

250

1331

368

1325

418

350

CFM/ton

CFM

W

atts

1228

/

1336

152

/

185

1235

/

1246

212

/

215

1232

/

1056

319

/

253

1232

/

1056

319

/

253

1224

/

955

365

/

259

400

CFM/ton

CFM

W

atts

1388

211

1398

279

1400

343

1399

403

1395

457

370

CFM/ton

CFM

W

atts

1292

/

1400

174

/

210

1300

/

1313

237

/

241

1299

/

1132

350

/

281

1401

/

1244

402

/

328

1292

/

1036

399

/

288

420

CFM/ton

CFM

W

atts

1455

240

1465

312

1468

379

1469

441

1463

497

390

CFM/ton

CFM

W

atts

1356

/

1465

198

/

238

1366

/

1381

265

/

270

1367

/

1207

384

/

312

1575

/

1434

505

/

422

1361

/

1115

435

/

320

440

CFM/ton

CFM

W

atts

1523

272

1534

347

1538

418

1538

483

1534

542

4

tons

†

330

CFM/ton

CFM

W

atts

1315

/

1443

212

/

228

1324

/

1358

247

/

260

1323

/

1181

362

/

301

1170

/

1010

293

/

237

1316

/

1088

412

/

308

380

CFM/ton

CFM

W

atts

1502

262

1514

337

1518

406

1518

471

1514

529

350

†

CFM/ton

CFM

W

atts

1389

/1517

212

/

262

1399

/

1436

280

/

295

1401

/

1266

402

/

338

1401

/

1266

402

/

338

1395

/

1177

455

/

346

400

CFM/ton

CFM

W

atts

1582

302

1594

382

1598

454

1598

522

1591

581

370

CFM/ton

CFM

W

atts

1465

/

1594

245

/

301

1476

/

1516

317

/

335

1480

/

1352

446

/

379

1600

/

1483

521

/

450

1475

/

1267

502

/

388

420

CFM/ton

CFM

W

atts

1664

348

1675

421

1680

508

1678

577

1669

638

390

CFM/ton

CFM

W

atts

1543

/

1673

283

/

346

1555

/

1597

359

/

380

1560

/

1439

495

/

425

1793

/

1701

663

/

592

1554

/

1356

553

/

434

440

CFM/ton

CFM

W

atts

1748

400

1758

486

1760

565

1755

634

1708

668

4.5

tons**

330

CFM/ton

CFM

W

atts

1470

/

1599

247

/

304

1481

/

1521

319

/

337

1485

/

1357

449

/

382

1309

/

1165

355

/

294

1480

/

1272

505

/

391

380

CFM/ton

CFM

W

atts

1695

367

1706

451

1710

528

1707

598

1697

659

350

CFM/ton

CFM

W

atts

1558

/

1688

290

/

354

1570

/

1613

367

/

389

1575

/

1455

505

/

434

1575

/

1455

505

/

434

1568

/

1373

563

/

444

400

CFM/ton

CFM

W

atts

1790

428

1799

515

1799

594

1792

664

1700

661

370

CFM/ton

CFM

W

atts

1649

/

1780

340

/

412

1661

/

1707

422

/

447

1664

/

1554

565

/

493

1793

/

1701

663

/

592

1655

/

1475

625

/

503

420

CFM/ton

CFM

W

atts

1885

496

1889

584

1884

662

1783

656

1683

648

390

CFM/ton

CFM

W

atts

1742

/

1873

397

/

477

1754

/

1801

483

/

512

1751

/

1653

630

/

558

1749

/

1749

637

/

637

1708

/

1576

666

/

567

440

CFM/ton

CFM

W

atts

1976

568

1973

655

1871

652

1765

643

1667

636

•

†

F

actory

Setting

•

**

Not

an

actual

OD

size

•

Status

LED

will

blink

once

per

100

CFM

requested.

In

torque

mode,

actual

airflow

may

be

lower

.

•

T

orque

mode

will

reduce

airflow

when

static

is

above

approximately

0.4”

water

column.

•

If

the

air

handler

is

applied

in

downflow

or

horizontal

configurations,

the

airflow

should

not

exceed

2000

CFM.

Airflow

above

2000

CFM

could

result

in

water

blow-

off

.

•

All

heating

modes

default

to

Constant

CFM.

•

Cooling

airflow

values

are

with

wet

coil,

no

filter

MINIMUM

HEATER

AIRFLOW

CFM

—

HEATER

MATRIX

MODEL

NO.

BA

YEV

AC04BK1AA

BA

YEV

AC04LG1AA

BA

YEV

AC05BK1AA

BA

YEV

AC05LG1AA

BA

YEV

AC08BK1AA

BA

YEV

AC08LG1AA

BA

YEV

AC10BK1AA

BA

YEV

AC10LG1AA

BA

YEV

AC10LG3AA

BA

YEVCB15LG3AA

BA

YEVBC15BK1AA

BA

YEVBC20BK1AA

BA

YEVCC25BK1AA

T

AM7A0C48

1063

/

1188

1063

/

1500

1125

/

1500

1000

/

1188

1125

/

1563

1250

/

1625

1500

/

1750

1625

/

1813

WITHOUT

HEA

T

PUMP

/

WITH

HP

—

SEE

AIR

HANDLER

NAMEPLA

TE

Note:

Minimum

auxiliary

heating

airflow

is

automatically

configured

by

the

air

handler

model

and

the

auxiliary

heater

model

number.

This

is

not

field

adjustable.