24

TAM7-SF-2E-EN

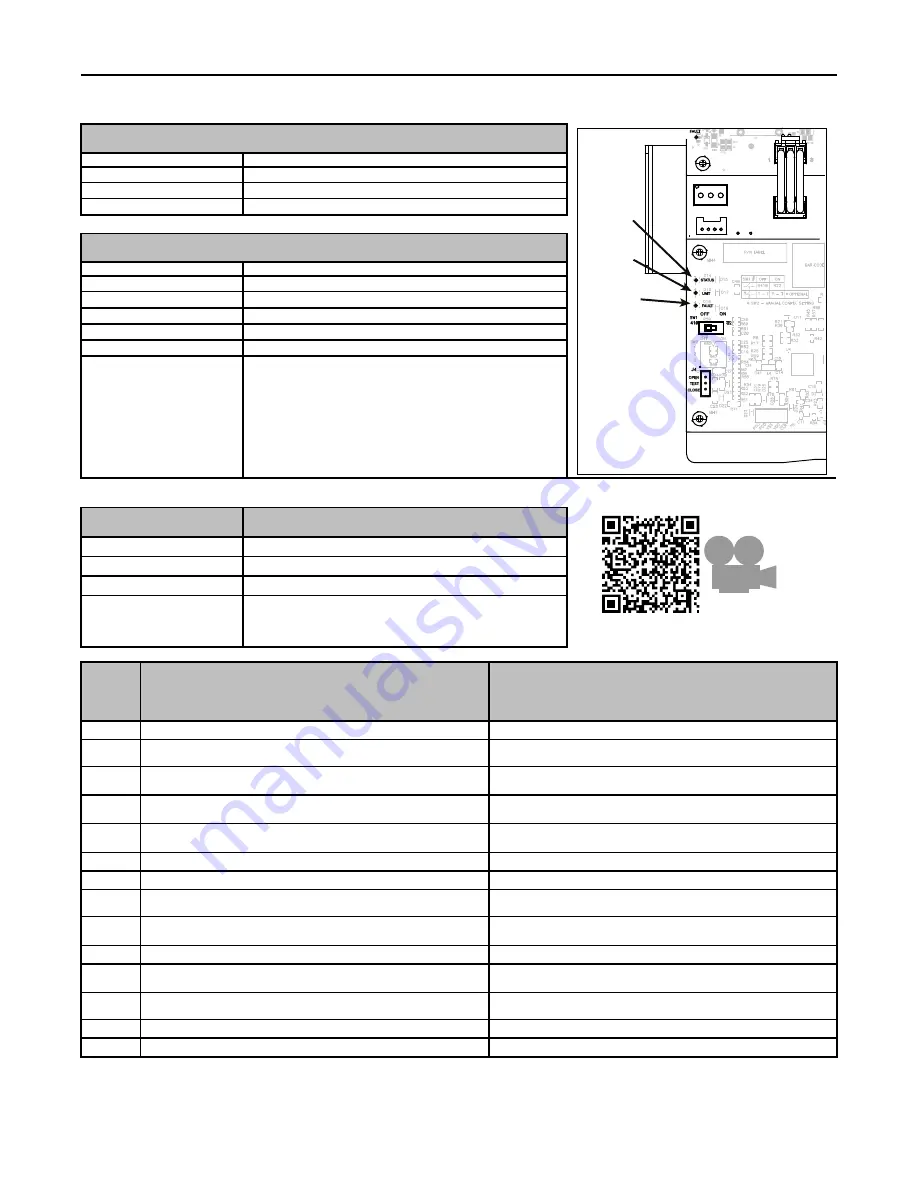

EVC STATUS LED (GREEN)

(Non-Heat Pump Systems)

FAULT

R80

R70

D

D28

R73

R100

K2

J 4

TEST

CLOSE

410

FAULT

UNIT

22

OPEN

STATUS

FAULT

OFF

ON

STATUS

LED

FAULT

LED

UNIT

LED

Flash

1

Cool mode selected / No active call

2

Active call for 1st stage cooling

3

Active call for 2nd stage cooling

(a)

EVC STATUS LED (GREEN)

(Heat Pump Systems)

Flash

1

Cool mode selected / No active call

2

Active call for 1st stage cooling or defrost

3

Active call for 2nd stage cooling or defrost

4

Heat mode selected or Thermostat system switch off

5

Active call for 1st stage heating

6

Active call for 2nd stage heating

(a)

Single stage OD systems will report 2nd stage flash codes.

UNIT LED (BLUE)

DESCRIPTION

Click or Scan to see a video on EVC Fault

Codes

1 Flash

Normal (1 flash every 4 seconds)

Rapid

Communication Busy Error (2 flashes per second)

SOLID ON

Communications cannot be establish with the AFC

Off

No Power

EVC

FAULT

LED

(RED)

DESCRIPTION

POSSIBLE CAUSES

OFF

Standby

1

Stepper Motor or wiring harness has an open circuit or

intermittent short.

Faulty EEV motor / wiring harness.

2

Control has detected an internal failure

Verify EEV motor & harness resistance. EEV motor drive, motor

feedback, or 12v failure

3

Evaporator Temperature Sensor (ET) input out of range

(a)

Sensor open / shorted, unplugged, wiring harness problem. Verify

5VDC output from control

4

Gas Temperature Sensor (GT) input out of range

Sensor open / shorted, unplugged, wiring harness problem. Verify

5VDC output from control

5

Stepper Motor Coil is shorted

(b)

Faulty EEV motor / wiring harness

6

Valve is not responding to a change in position.

Possible stuck valve, ET/GT sensor calibration

7

High superheat

System low on charge, liquid line restriction, ET/GT sensor

calibration

10

Low superheat

(c)

Stuck valve, ET/GT sensor calibration, restricted distributor line

that ET is connected to, check valve leaking

11

Condensate drain switch activated for 100 seconds

Condensate line clogged, clean switch

13

Indoor frost protection activated

(TAM8 unit will disable all

operation for 30 minutes to allow coil defrost)

Low / incorrect airflow, low refrigerant charge, ET sensor

calibration. Normal for low ambient cooling

14

Internal communication fault (All operation is terminated)

Verify harness continuity between J2 of the EVC and J4 of the

Distribution Board

15

Configuration fault (All operation is terminated)

Check if PM error is present, cycle power to the unit

16

Outdoor status fault (All operation is terminated)

Cycle power to the unit, replace EVC if error persists

(a)

EEV will try to go to a safe position, cooling attempt allowed

(b)

K1 relay opens on EVC, YO disabled

(c)

Cooling attempt allowed, 5 consecutive Y calls with same condition disables YO