18-GJ83D1-1C-EN

25

Table 13.

Braze the Refrigerant Lines (continued)

4.

Connect, but do not braze field line set to indoor coil.

a.

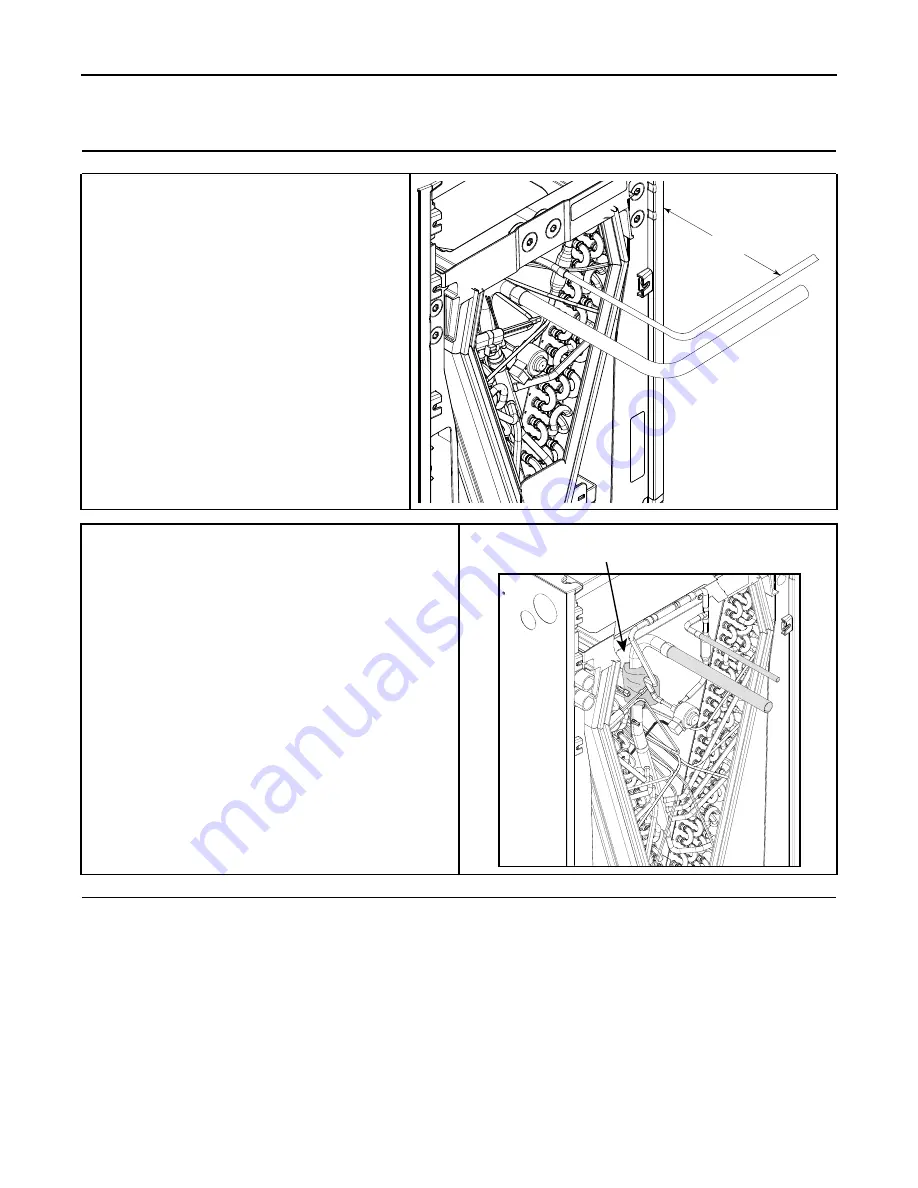

Allow a minimum of 1.5 inches of refrigerant line set

before using an elbow coupling.

Important:

Service access to the auxiliary heater must

remain unobstructed.

1.5” MIN

Important:

Heat Sensitive Sensor. The temperature Sensor must be

removed or a wet rag must be wrapped around the

suction line between the Sensor and the braze joint to

protect the Sensor from failure due to overheating.

5.

Braze refrigerant line connections.

a.

Pull back the insulation before brazing the suction line.

b.

Wrap the Gas Temperature Sensor (GT) with a wet rag.

c.

Braze the refrigerant line connections.

Important:

Care must be taken during brazing to avoid damage to

unit components and wiring.

Note:

The suction line must be insulated prior to brazing the line set

to the air handler stubs.

Wet Rag on Gas Temperature Sensor (GT)