18-GF74D1-1K-EN

15

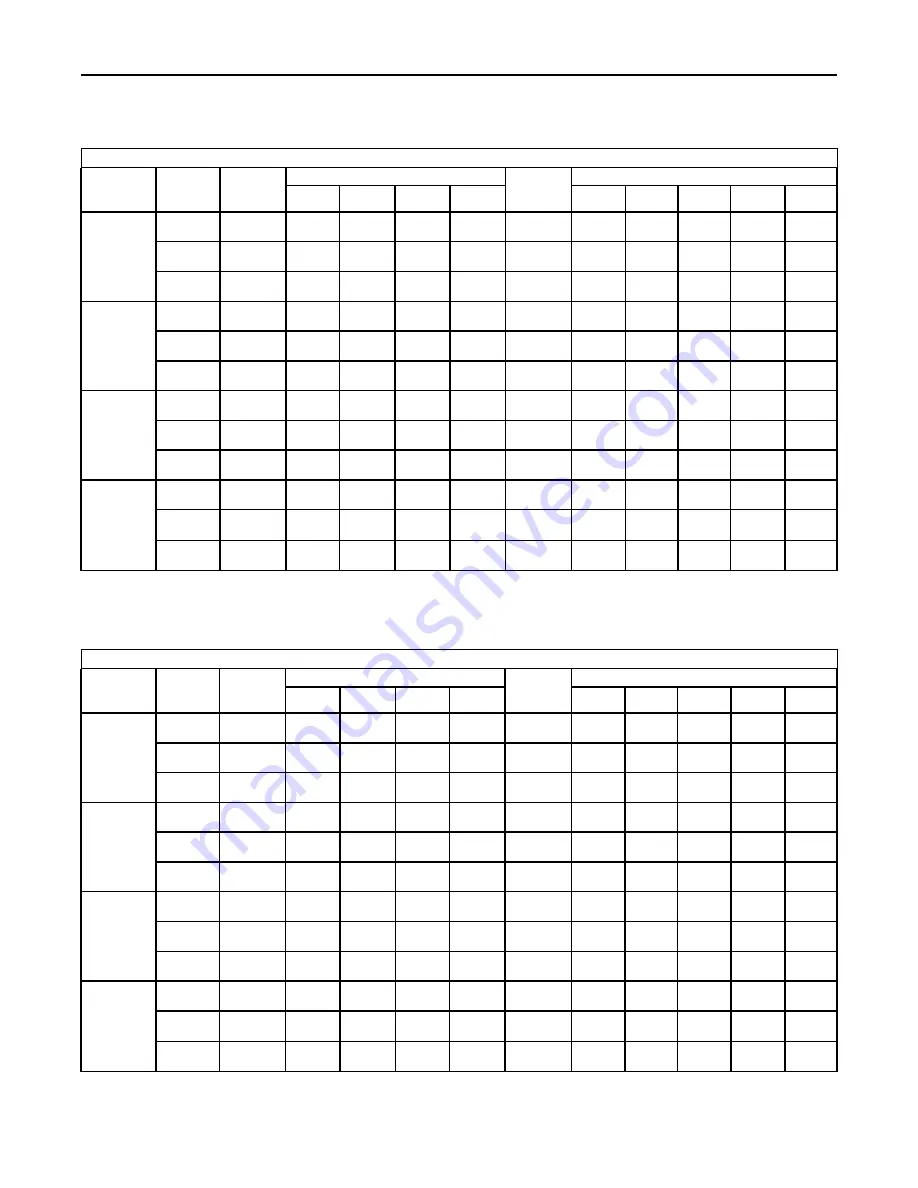

Table 10.

Air Flow Performance

TEM6A0C48H41SB, TEM6A0C60H51SB COOLING AIRFLOW PERFORMANCE, WET COIL, NO FILTER, NO HEATER

OUTDOOR

UNIT SIZE

(TONS)

SPEED

SETTING

AIRFLOW

SETTING

DIP SWITCH SETTING

AIRFLOW

POWER

EXTERNAL STATIC PRESSURE

SW1

SW2

SW3

SW4

0.1

0.3

0.5

0.7

0.9

3

LOW

324 CFM/

ton

ON

ON

OFF

ON

CFM

Watts

991

89

985

133

974

186

984

237

994

303

NORMAL

368 CFM/

ton

ON

ON

OFF

OFF

CFM

Watts

1120

118

1119

167

1110

224

1116

279

1122

333

HIGH

423 CFM/

ton

ON

ON

ON

OFF

CFM

Watts

1282

162

1286

219

1281

280

1280

343

1282

402

3.5

LOW

314 CFM/

ton

OFF

ON

OFF

ON

CFM

Watts

1116

117

1114

165

1105

222

1111

277

1117

331

NORMAL

357 CFM/

ton

OFF

ON

OFF

OFF

CFM

Watts

1263

156

1266

212

1261

273

1261

334

1263

392

HIGH

411 CFM/

ton

OFF

ON

ON

OFF

CFM

Watts

1449

218

1458

287

1456

352

1449

421

1447

496

4

LOW

298 CFM/

ton

ON

OFF

OFF

ON

CFM

Watts

1207

140

1208

193

1201

252

1203

311

1207

366

NORMAL

339 CFM/

ton

ON

OFF

OFF

OFF

CFM

Watts

1368

190

1374

252

1370

315

1367

381

1367

448

HIGH

389 CFM/

ton

ON

OFF

ON

OFF

CFM

Watts

1564

264

1577

343

1577

411

1567

484

1561

570

5

LOW

305 CFM/

ton

OFF

OFF

OFF

ON

CFM

Watts

1534

251

1545

328

1545

394

1536

467

1531

550

NORMAL

(a)

347 CFM/

ton

OFF

OFF

OFF

OFF

CFM

Watts

1740

344

1758

444

1762

518

1745

594

1734

684

HIGH

(b)

399 CFM/

ton

OFF

OFF

ON

OFF

CFM

Watts

1995

484

2022

629

2030

717

2005

783

1987

828

(a)

Factory Default Setting

(b)

Airflow must not exceed 1800 cfm in horizontal right, horizontal left, and downflow applications due to condensate blowoff. The 5 ton high tap shall not be

used in these applications.

Table 11.

Air Flow Performance

TEM6A0C48H41SB, TEM6A0C60H51SB HEATING AIRFLOW PERFORMANCE, NO FILTER, NO HEATER

OUTDOOR

UNIT SIZE

(TONS)

SPEED

SETTING

AIRFLOW

SETTING

DIP SWITCH SETTING

AIRFLOW

POWER

EXTERNAL STATIC PRESSURE

SW1

SW2

SW3

SW4

0.1

0.3

0.5

0.7

0.9

3

LOW

360 CFM/

ton

ON

ON

OFF

ON

CFM

Watts

1097

112

1094

160

1086

216

1092

271

1099

326

NORMAL

400 CFM/

ton

ON

ON

OFF

OFF

CFM

Watts

1215

142

1216

196

1210

255

1211

314

1215

369

HIGH

440 CFM/

ton

ON

ON

ON

OFF

CFM

Watts

1333

178

1338

238

1333

300

1331

365

1332

428

3.5

LOW

348 CFM/

ton

OFF

ON

OFF

ON

CFM

Watts

1232

147

1234

202

1228

261

1229

322

1233

377

NORMAL

387 CFM/

ton

OFF

ON

OFF

OFF

CFM

Watts

1366

189

1373

252

1369

314

1366

381

1365

447

HIGH

426 CFM/

ton

OFF

ON

ON

OFF

CFM

Watts

1500

238

1511

311

1510

377

1502

449

1498

529

4

LOW

338 CFM/

ton

ON

OFF

OFF

ON

CFM

Watts

1364

188

1370

251

1366

313

1363

379

1363

446

NORMAL

375 CFM/

ton

ON

OFF

OFF

OFF

CFM

Watts

1509

241

1520

315

1519

382

1511

453

1506

535

HIGH

413 CFM/

ton

ON

OFF

ON

OFF

CFM

Watts

1659

305

1674

395

1676

466

1662

541

1654

632

5

LOW

326 CFM/

ton

OFF

OFF

OFF

ON

CFM

Watts

1637

295

1652

383

1653

453

1641

528

1632

618

NORMAL

(a)

362 CFM/

ton

OFF

OFF

OFF

OFF

CFM

Watts

1814

381

1834

493

1839

570

1820

645

1807

730

HIGH

398 CFM/

ton

OFF

OFF

ON

OFF

CFM

Watts

1990

481

2017

625

2025

713

2000

779

1982

826

(a)

Factory Default Setting