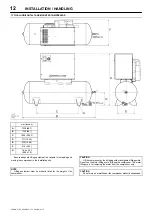

INSTALLATION / HANDLING

13

UP6RD–5–175, UP6RM–5–175, UP6RD–5–175

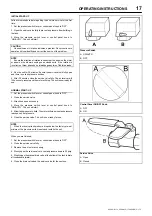

Use suitable lifting equipment (i.e. forklift) to lift and transport the

compressor to the installation site. Ensure the lifting equipment, straps,

etc. are capable of supporting the weight of the compressor.

Ensure that the correct fork lift truck slots or marked lifting / tie down

points are used whenever the compressor is lifted or transported.

A Fork lift

B Lifting straps

UNPACKING

The compressor will normally be delivered with a polythene cover.

If a knife has to be used to remove this cover ensure that the exterior

paintwork of the compressor is not damaged.

Ensure that all transport and packing materials are discarded.

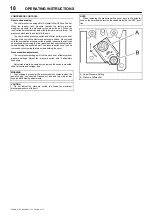

Enclosed compressors are shipped with shipping blocks to protect

the vibration mounts. The front panel needs to be removed by

unscrewing the 4 captive fasteners. The two wooden blocks are

between the subbase and the bottom panel. These can be loosened

after unscrewing and removing the two shipping screws underneath

the bottom panel. Unscrewing the two shipping screws will release the

subbase and will then be supported on the vibration mounts. DO NOT

RUN THE COMPRESSOR WITHOUT REMOVING THE SHIPPING

BLOCKS AND SHIPPING SCREWS.

A. Shipping screws both ends [2]

B. Wooden shipping blocks [2]

LOCATION IN THE PLANT

WARNING FOR COMPRESSORS EQUIPPED WITH ELECTRIC

DRAIN VALVE

WARNING

The electric drain valve incorporates arcing or sparking parts, such

as snap switches, receptacles and the like that tend to produce arcs or

sparks and, therefore, when located in a garage, the compressor

should be in a room or enclosure provided for the purpose, or the

electric drain valve should be 18 inches (457 mm) or more above the

floor.

Consult local officials for information regarding acceptable noise

levels in your area. Enclosed compressors are available for low noise

applications.

The compressor must be permanently mounted to a firm, level floor

capable of supporting it. Ensure that the compressor is positioned

securely and on a stable foundation. Any risk of movement should be

removed by suitable means, especially to avoid strain on any rigid

discharge piping.

WARNING

Remove the compressor from the skid before mounting.

When mounting the compressor, install bolts through the mounting

feet and into the mounting surface. Do not bolt uneven feet tightly to the

foundation, as this will cause excessive stress on the receiver tank.

Use metal shims to level the compressor if necessary.

Summary of Contents for UP6RD-5-175

Page 2: ......