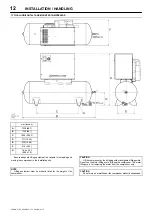

INSTALLATION / HANDLING

14

UP6RD–5–175, UP6RM–5–175, UP6RD–5–175

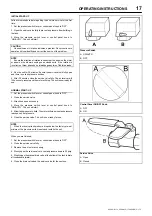

Typical Permanent Mounting (Customer–Supplied Hardware)

A. 3/8” Lag screw

B. Floor line

C. Lag screw anchor for concrete

D. Shim beneath isolator washer, if necessary

E. Isolator washer

F. Flat washer

CAUTION

Never operate in temperatures below 20

_

F (–6.6

_

C) or above

104

_

F (40

_

C).

REMOTE AIR INLET PIPING

If the air around the compressor is relatively free of dirt, install the

air inlet filter at the inlet connection at the pump. If the air is dirty, pipe

the filter to a source of clean air. Use PVC plastic tubes for remote inlet

piping. Do not use black pipe or galvanized pipe, as these promote

sweating and rust. Consider installing an in–line type filter for ease of

cleaning and replacement. Make the line as short and direct as possible

and as large, or larger, than the diameter of the inlet connection on the

pump. Do not install piping with a diameter lower than that of the pump

intake.

Increase the pipe diameter one size for every 10 feet (3 m) of length

or every 90

_

bend. Make sure the piping is adequately braced.

If you pipe the filter outdoors, cover it with a hood to prevent the

entrance of rain or snow.

Heavy duty filter elements and filtration equipment are available for

fine airborne dust, such as cement and rock dust.

CAUTION

Do not operate the compressor without the air inlet filter(s).

DISCHARGE PIPING

If it is necessary to install air discharge and condensate discharge

piping, adhere to the following guidelines. Contact your dealer for more

information.

WARNING

Do not use plastic pipe, soldered copper fittings, rubber hose, or

lead–tin soldered joints anywhere in the compressed air system.

WARNING

If an aftercooler, check valve, block valve, or any other restriction

is added to the compressor discharge, install a properly sized coded

safety/relief valve between the compressor discharge and restriction.

CAUTION

If you will be using the “All Season Select” synthetic compressor

lubricant, all downstream piping material and system components must

be compatible. Refer to the material compatibility list. If there are

incompatible materials present in your system, or if there are materials

not included in the list, contact your dealer.

Materials Compatibility List

Suitable:

Viton

R

, Teflon

R

, Epoxy (Glass Filled), Oil Resistant Alkyd,

Fluorosilicone, Fluorocarbon, Polysulfide, 2–Component Urethane,

Nylon, Delrin

R

, Celcon

R

, High Nitrile Rubber (Buna N. NBR more than

36% Acrylonitrile), Polyurethane, Polyethylene, Epichlorohydrin,

Polyacrylate, Melamine, Polypropylene, Baked Phenolics, Epoxy,

Modified Alkyds

(

R

indicates trademark of DuPont Corporation)

Not Recommended:

Neoprene, Natural Rubber, SBR Rubber, Acrylic Paint, Lacquer,

Varnish, Polystyrene, PVC, ABS, Polycarbonate, Cellulose Acetate,

Low Nitrile Rubber (Buna N. NBR less than 36% Acrylonitrile), EPDM,

Ethylene Vinyl Acetate, Latex, EPR, Acrylics, Phenoxy, Polysulfones,

Styrene Acrylonitrile (San), Butyl

The piping, fittings, receiver tank, etc. must be certified for at least

the maximum working pressure of the unit. Use hard–welded or

threaded steel or copper pipes and cast iron fittings that are certified

safe for the unit’s discharge pressure and temperature. DO NOT USE

PVC PLASTIC. Use pipe thread sealant on all threads, and make up

joints tightly to prevent air leaks.

If installing a condensate discharge line, the piping must be at least

one size larger than the connection, as short and direct as possible,

secured tightly and routed to a suitable drain point. Condensate must

be disposed of in accordance with local, state, and federal laws and

regulations.

WARNING

On baseplate mounted units, you must connect the pressure switch

to a suitable air receiver tank before operating the unit.

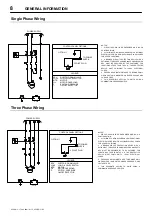

ELECTRICAL WIRING

WARNING

Electrical installation and service should be performed by a qualified

electrician who is familiar with all the applicable local, state and federal

laws and regulations.

NOTE

This product should be connected to a grounded, metallic,

permanent wiring system, or an equipment–grounding terminal or lead

on the product.

The motor rating, as shown on the motor nameplate or compressor

specification label, and the power supply must have compatible

voltage, phase and hertz characteristics.

The electrical wiring between the power supply and electric motor

varies according to motor power. Power leads must be adequately

sized to protect against excessive voltage drop during start–up. Refer

to National Electric Code (NEC) or applicable local code to get proper

information on wiring size. DO NOT USE UNDERSIZE WIRE.

Summary of Contents for UP6RD-5-175

Page 2: ......