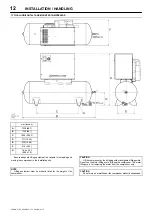

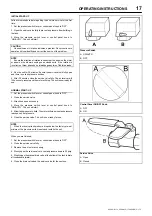

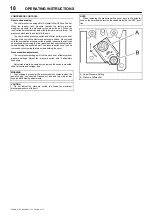

INSTALLATION / HANDLING

15

UP6RD–5–175, UP6RM–5–175, UP6RD–5–175

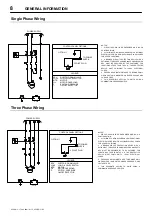

NOTE: Wire sizes are given in AWG(SWG)

MOTOR POWER

SINGLE PHASE

THREE PHASE

5HP (3.7kW)

115V

230V

200V

230V

460V

575V

4 (6)

8 (10)

10 (12)

12 (14)

14 (16)

14 (16)

Refer to National Electric Code or applicable local codes to

determine proper fusing or circuit breaker rating. If using fuses,

time–delay or slow–blow fuses are recommended.

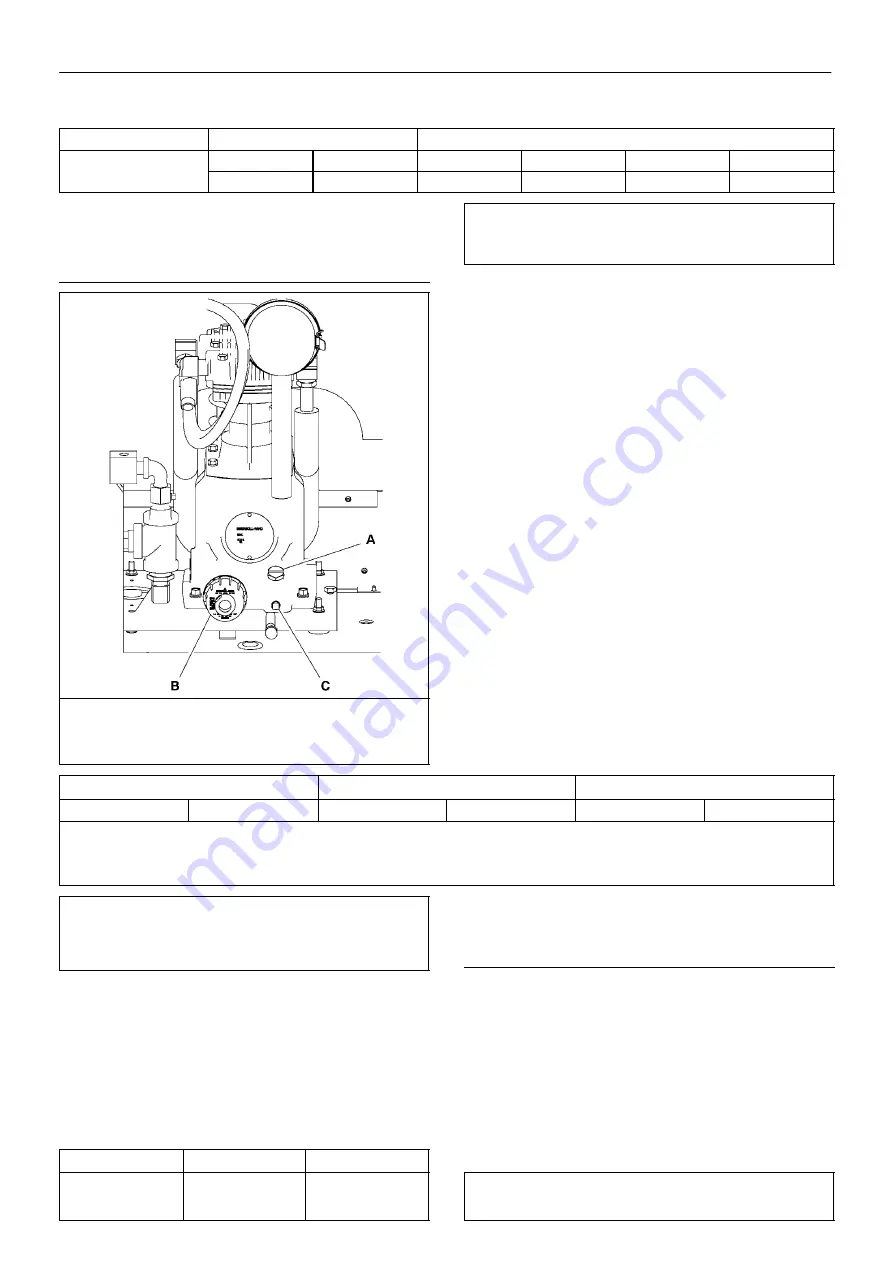

COMPRESSOR LUBRICATION

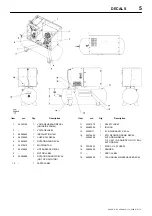

A. Oil fill plug

B. Low oil level switch

C. Oil drain plug

CAUTION

Do not operate without lubricant or with inadequate lubricant.

Ingersoll–Rand is not responsible for compressor failure caused by

inadequate lubrication.

We recommend ALL SEASON SELECT synthetic compressor

lubricant.

You may use a petroleum–based lubricant that is premium quality,

does not contain detergents, contains only anti–rust, anti–oxidation,

and anti–foam agents as additives, has a flashpoint of 440

_

F (227

_

C)

or higher, and has an auto–ignition point of 650

_

F (343

_

C) or higher.

See the petroleum lubricant viscosity table below. The table is

intended as a general guide only. Heavy–duty operating conditions

require heavier oil viscosity. Refer specific operating conditions to your

dealer for recommendations.

Temperature Around Compressor

Viscosity @ 37.8

_

C(100

_

F )

Viscosity Grade

_

F

_

C

SUS

Centistokes

ISO

SAE

<40

<4.4

150

32

32

10

40 – 80

4.4 – 26.7

500

110

100

30

80 – 104

26.7 – 40

750

165

150

40

NOTE

If you use a petroleum–based compressor lubricant at start–up and

decide to convert to ALL SEASON SELECT lubricant later, the

compressor valves must be thoroughly decarbonized and the

crankcase must be flushed before conversion.

Filling Procedures:

1. For enclosed compressors, remove the front panel.

2. Unscrew and remove the oil fill plug.

CAUTION

Do not remove the oil fill plug while the compressor is running.

3. Slowly fill the crankcase with lubricant until the lubricant reaches the

top thread of the oil fill opening and the top of the sight glass.

MODEL

OUNCES

LITERS

UP6RD–5–175

UP6RM–5–175

UP6RX–5–175

40

1.2

4. Replace the oil fill plug HAND TIGHT ONLY.

LOW OIL LEVEL SWITCH

A float activated low oil level switch may be installed to protect your

unit against damage due to insufficient compressor level oil. Low oil

level in the compressor crankcase causes the switch contacts to close,

thus energizing the shunt coil in the combination pressure switch. This

in turn shuts the pressure switch off. Once proper oil level has been

restored the pressure switch (control panel) lever needs to be turned

to Auto to start the unit.

Proper protection against low oil level depends on proper

adjustment of the low oil level switch. During the initial run, stop the unit

and drain one quart (0.946L) of oil from the compressor crankcase into

a suitable clean container. Listen for the switch to click or check the

switch with a continuity tester.

NOTE

On enclosed compressors, the front panel must be removed to

access the low oil level switch.

Summary of Contents for UP6RD-5-175

Page 2: ......