OPERATING INSTRUCTIONS

17

UP6RD–5–175, UP6RM–5–175, UP6RD–5–175

INITIAL START–UP

Follow this procedure before putting the unit into service for the first

time:

1. Set the pressure switch lever or control panel knob to ”OFF”.

2. Open the service valve fully to prevent air pressure from building in

the tank.

3. Move the pressure switch lever or control panel knob to

”ON/AUTO”. The unit will start.

CAUTION

Unusual noise or vibration indicates a problem. Do not continue to

operate until you identify and correct the source of the problem.

NOTE

Ensure the direction of rotation is correct per the arrow on the motor

or arrow on the blower housing on enclosed units. If the rotation is

incorrect on three–phase units, interchange any two of the three leads.

4 Run the unit for 30 minutes. Ensure the service valve is fully open

and there is no tank pressure build up.

5. After 30 minutes, close the service valve fully. The air receiver will

fill to cut–out pressure and the motor will stop. The unit is now ready for

use.

NORMAL START–UP

1. Set the pressure switch lever or control panel knob to ”OFF”.

2. Close the service valve.

3. Attach hose and accessory.

4. Move the pressure switch lever or control panel knob to

”ON/AUTO”. The unit will start.

5. Allow tank pressure to build. The motor will stop when tank pressure

reaches cut–out pressure.

6. Open the service valve. The unit is now ready for use.

NOTE

When the receiver tank pressure drops below the factory pre–set

minimum, the pressure switch resets and restarts the unit.

When you are finished:

1. Set the pressure switch lever or control panel knob to ”OFF”.

2. Close the service valve fully.

3. Remove the air tool or accessory.

4. Slowly open the service valve to vent air pressure down to 20 psig.

5. Slowly open the manual drain valve at the bottom of the tank to drain

all condensate (water).

6. Close the drain valve and the service valve for the next use.

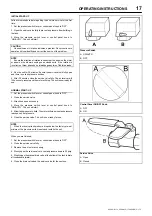

Pressure Switch

A. ON/AUTO

B. OFF

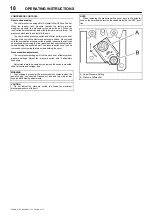

Control Panel ON/OFF Knob

A. OFF

B. ON

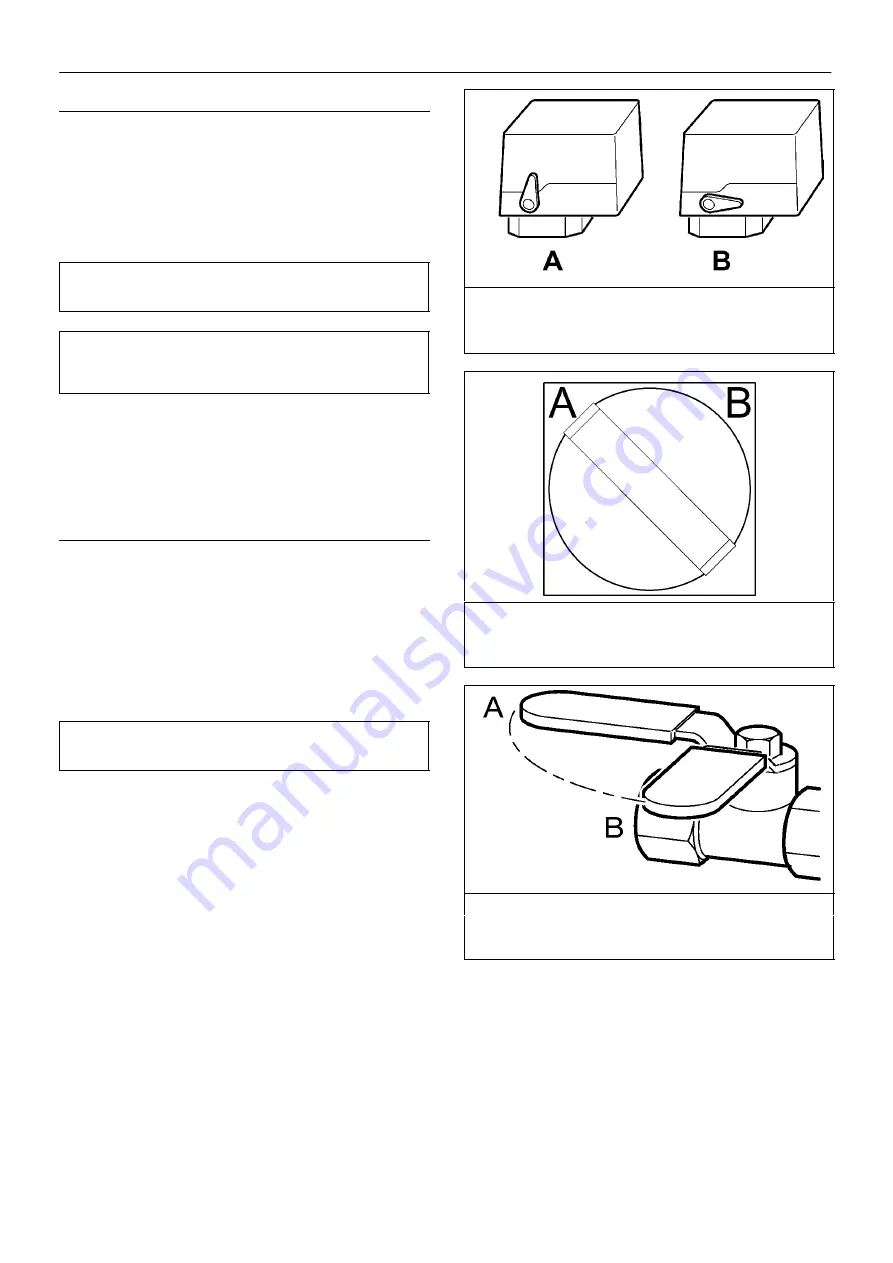

Service Valve

A. Open

B. Closed

Summary of Contents for UP6RD-5-175

Page 2: ......