OPERATING INSTRUCTIONS

18

UP6RD–5–175, UP6RM–5–175, UP6RD–5–175

COMPRESSOR CONTROLS

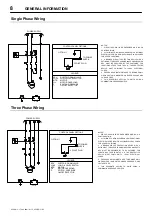

Direct online starting:

The compressor is equipped for Automatic Start & Stop Control.

When the receiver tank pressure reaches the factory pre–set

maximum pressure, the pressure switch stops the unit. When the

receiver tank pressure drops below the factory pre–set minimum. The

pressure switch resets and restarts the unit.

The combination pressure switch and starter performs the dual

function of a direct online starter and a pressure switch. On enclosed

units the combination pressure switch is behind the control panel. It can

be accessed by removing the front panel and then unscrewing the four

screws holding the control panel. The pressure switch cover can be

removed by unscrewing the two screws holding the cover.

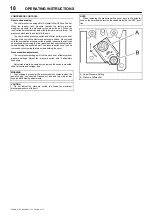

Pressure switch adjustment:

The compressor package will cut–in and cut–out at factory preset

pressure settings. Adjust the pressure switch only if absolutely

necessary.

Adjustments are to be carried out only when the switch is mounted,

under pressure and voltage–free.

WARNING

High voltage is present at the pressure switch contacts when the

power supply is connected. Disconnect, lock and tag main power

supply before making adjustments.

CAUTION

Do not adjust the pressure switch to exceed the maximum

discharge pressure of the unit.

NOTE

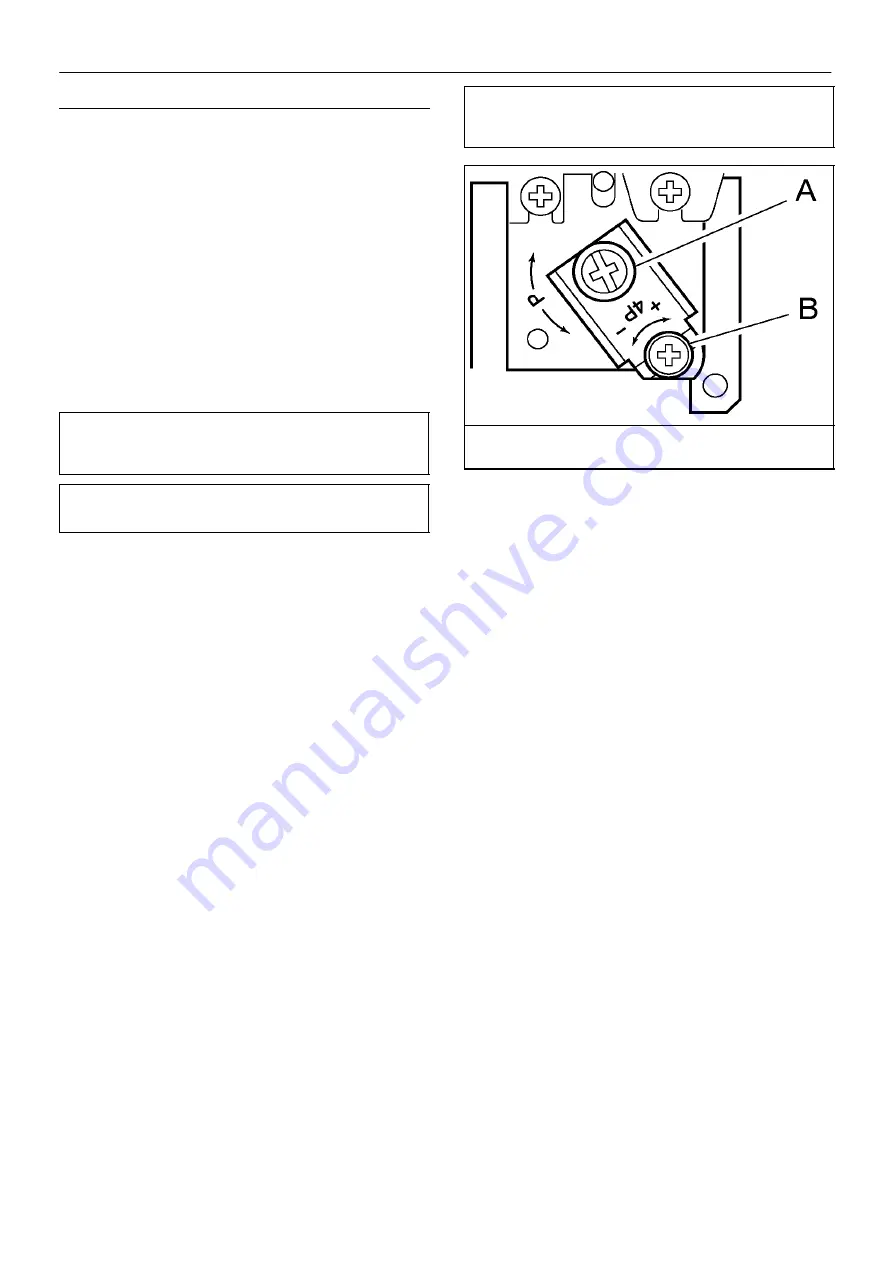

When replacing the pressure switch cover, ensure the selector

knob on the cover and the lever on the switch are both in the ”OFF” posi-

tion.

A. Upper Pressure Setting

B. Pressure Differential

Summary of Contents for UP6RD-5-175

Page 2: ......