MAINTENANCE

20

UP6RD–5–175, UP6RM–5–175, UP6RD–5–175

OIL CHANGE PROCEDURE

1. Remove the oil drain plug and allow the oil to drain into a suitable

container.

2. Replace the oil drain plug.

3. Follow the filling procedures in INSTALLATION / HANDLING

section.

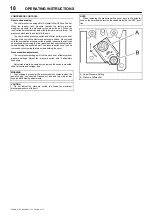

BELT CHECKING AND ADJUSTMENT PROCEDURE

Check belt tension occasionally, especially if looseness is

suspected. A quick check to determine if adjustment is proper may be

made by observing the slack side of the belt for a slight bow when the

unit is in operation. If a slight bow is evident, the belt is usually adjusted

satisfactorily.

On enclosed compressors, a belt tension measurement device can

be used to determine the tension of the belt. A belt inspection opening

is provided at the top of the blower housing.

Belt tensioning can be achieved by loosening the motor anchor

screws, pushing the motor away from the pump, and retightening the

motor anchor screws. The motor can be easily moved by placing a

prying tool beneath it. A commercially available spreader or other belt

tensioning device can also be helpful should tensioning be necessary.

On enclosed compressors, a belt tensioning bolt is provided to aid

in moving the motor.

Follow the procedures outlined below to correctly set and measure belt

tension.

1. Lay a straight edge across the top outer surface of the belt drive

from pulley to sheave.

2. At the center of the span, perpendicular to the belt, apply pressure

to the outer surface of the belt with a tension gauge. Force the belt to

the deflection indicated in the table below, and compare the reading on

the tension gauge to the figures shown.

Deflection in Inches

Min Tension (Lbs.)

Max. Tension (Lbs.)

0.17

3.0

6.0

Ensure the pulley and sheave are properly aligned and the motor

anchor screws are adequately retightened prior to restarting the

compressor.

CAUTION

Improper pulley/sheave alignment and belt tension can result in

motor overload, excessive vibration, and premature belt and/or bearing

failure.

To prevent these problems from occurring, ensure the pulley and

sheave are aligned and belt tension is satisfactory after installing new

belts or tensioning existing belts.

FILTER REPLACEMENT

1. Unscrew and remove the wing nut securing the filter housing to its

base.

2. Remove the filter housing and withdraw the old filter element.

3. Install a new filter element and replace the housing, securing it in

place with the wing nut.

ELECTRIC DRAIN VALVE

PRODUCT DESCRIPTION

The Electric Drain Valve removes condensed water and oil from the air

receiver tank. Additional drains may be installed throughout your

compressed air system, including aftercoolers, filters, drip legs and

dryers.

The Electric Drain Valve operates on a timer which can be set to

automatically drain the air receiver tank at operator–determined

intervals.

Key features include:

•

100% continuous duty

•

NEMA 4 enclosure

•

Adjustable time on (0.5 – 10 seconds)

•

Adjustable time off (0.5 – 45 minutes)

•

Stainless steel operator

•

LED to indicate electrical power is on

•

LED to indicate valve is open

•

Manual override

OPERATION

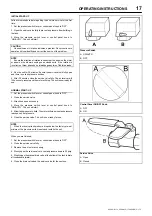

1. Open the strainer ball valve.

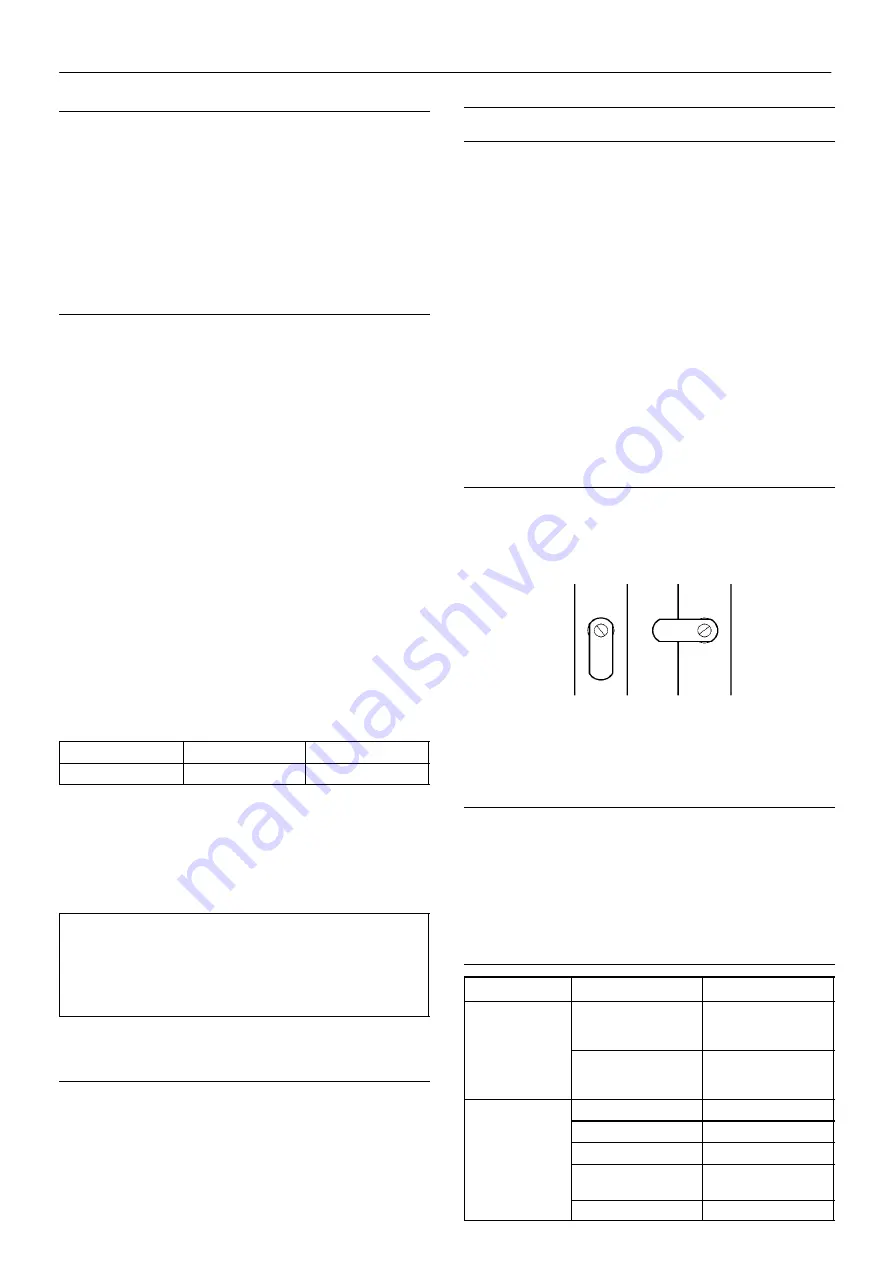

Strainer Ball Valve.

OPEN

CLOSED

2. Set the “time off” and “time on” knobs. See TIMER SETTINGS

(below) for an explanation of the settings.

3. During compressor operation, check for air leaks.

TIMER SETTINGS

The “time off” setting determines the interval between cycles from 30

seconds to 45 minutes. The “time on” setting determines the actual time

the compressor drains condensate.

The timer’s cycle rate and drain opening time should be adjusted to

open just long enough to discharge the condensate. The timer is

properly set when it opens and discharges condensate and then vents

air for approximately one second before closing. Adjustments may be

made depending on many factors, including humidity and duty cycle.

TROUBLESHOOTING

TROUBLE

CAUSE

ACTION

Valve will not

close.

1. Debris in solenoid

valve prevents dia-

phragm from seating.

1. Remove solenoid

valve, disassemble,

clean and reassemble

.

2. Short in electrical

component.

2. Check and replace

power cord or timer as

needed.

Timer will not

activate

1. No electrical supply.

1. Apply power.

activate

2. Timer malfunction

2. Replace timer.

3. Clogged port.

3. Clean valve.

4 Solenoid valve

malfunction.

4. Replace solenoid

valve.

5. Clogged strainer.

5. Clean strainer.

Summary of Contents for UP6RD-5-175

Page 2: ......