2

8

T

R

O

U

B

L

E

S

H

O

O

T

I

N

G

A

N

D

M

A

I

N

T

E

N

A

N

C

E

BRAKE LEVER ENGAGED

D

ISC BRA

KE ADJUSTMENT

If

you

determine

that

you

are

not

stopping

quickly

enough

or

your

stopping

distance

has

increased

when

you

fully

engage

the

brake

lever,

you

can

adjust

the

clamping

pressure

on

your disc brakes or adjust the disc brake actuator. Before performing the “clamping pressure

adjustment”,

make

sure

that

the

brake

actuator

is

fully

engaged

when

the

brake

lever

is

fully

depressed. This can be checked by fully depressing the brake lever and checking to make sure

that additional actuator movement is not possible by moving the actuator by hand.

5. The steering locking system and front wheel

assembly may loosen with use. Check this

frequently and tighten whenever loosened.

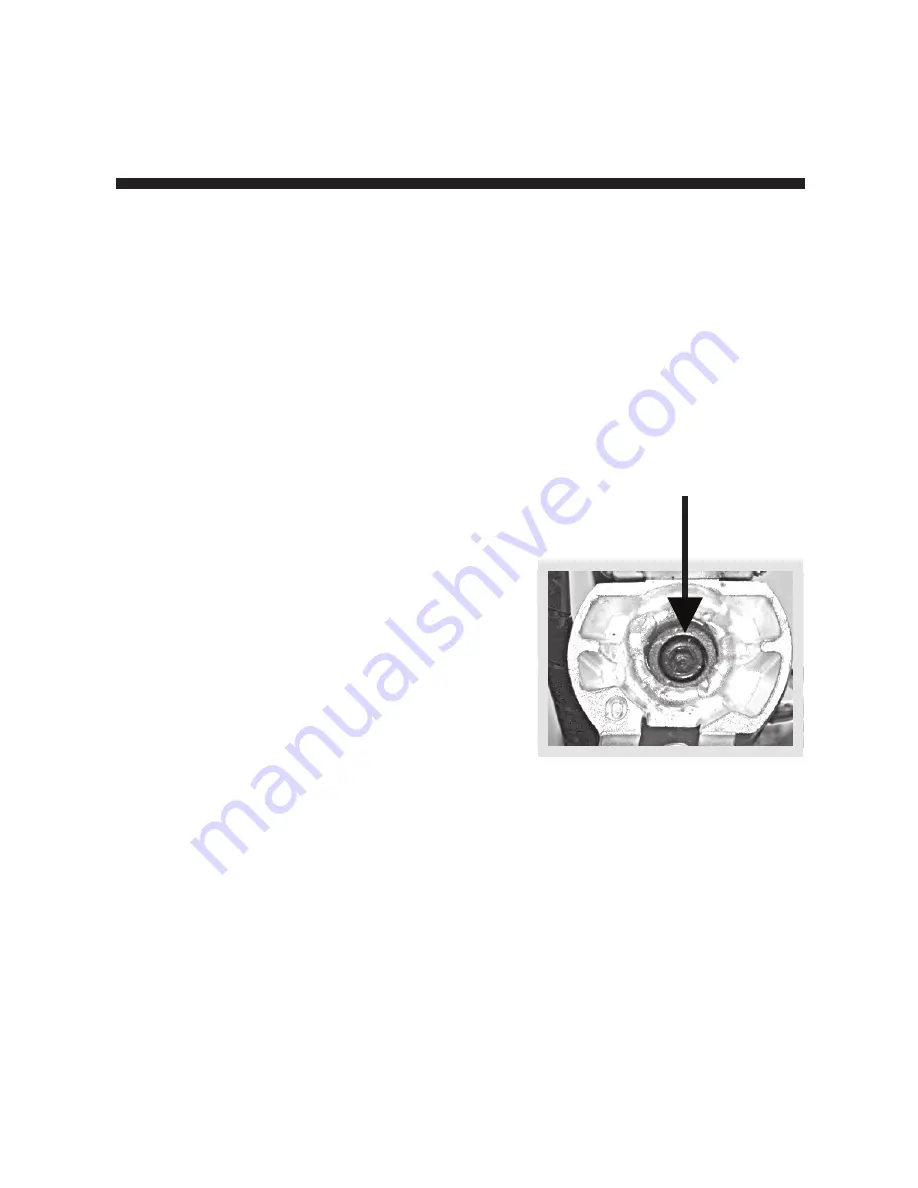

C E N T E R L O C K S C R E W

Your SmartScoot

TM

has been designed to be almost maintenance and service free

.

SmartScoot

TM

uses self-lubricating bearings throughout the scooter and

the

frame

is

constructed

using stainless steel. In addition, all parts can be can be cleaned with general

cleaning agents. However, there are a few maintenance items that may require your attention

from time to time. The following are the most likely adjustments that might be needed.

S

TEERING COLUMN AND FRONT WHEEL ALIGNMENT

If your front wheel is not perfectly lined up with your handle bars then you need to make an

adjustment to the front wheel lock mechanism. To adjust:

1. Using our Fold n Lock™ Technology, fold down the front

steering column by lifting the front lever and pulling the

latch down through the notch and clamp. With one

hand on the steering column use one finger from your

opposite hand to slide the latch sideways until the

steering column releases.

2. Use a 6mm Allen wrench to loosen the center screw

from the front wheel lock mechanism.

3. After the screw is loosened from the front wheel,

adjustments can be made and aligned as needed.

4. After adjustment, fully re-tighten the screw to secure

the alignment.