Page 15

EN

Chapter 4 Assembly and function

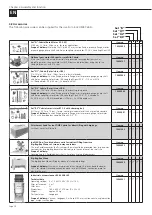

4.4.1.1 Frame with pull-out frame for pump hopper,

material hopper, water supply button and vibrator

The material hopper, the switching cabinet, the drive unit

for the mixer, the pull-out frame for the pump hopper incl.

the drive unit for the pump, the water measuring system

and the water supply button, the vibrator and the mixing

pipe are attached to the frame.

4.4.1.2 Switching cabinet

The switching cabinet is firmly connected to the frame of

the machine. All the necessary connections and controls for

operating the machine are located on the switching cabi-

net.

Connect the feed plug on the switching cabinet to the ex-

ternal power supply (400 V / 50 Hz). The cross-section of

the supply cable is at least 4.0 mm

2

at 400 V 3 PH! The small

silo inoCOMB Cabrio may only be operated with a permis-

sible RCD type B residual current circuit breaker (30 mA).

Switching cabinet, view from the front

4.4.1.3 Drive unit for the mixer

The mixer motor is firmly connected to the motor plate. For

cleaning purposes or to replace the metering shaft in the

material hopper, the unit can be folded away to the side.

The electrical connection plug of the motor is plugged into

the side of the switching cabinet.

4.4.1.4 Water measuring system

The water measuring system is firmly connected to the

frame of the machine. The connection for the external wa-

ter supply line (min. 3/4") is located on the water measuring

unit. The water supply button is also attached to the frame.

The water flow button and the needle valve are used to

make a rough adjustment of the water supply on the water

flow meter.

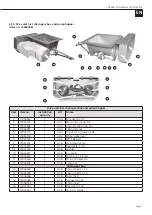

4.4.1.5 Mixing tube inoPOWER Mix with mixing shaft

and mixing tube cover

During transport, the mixing tube is dismantled and placed

in the pump hopper. This can be pushed under the material

hopper for transport. The opening for the mixing tube in

the material hopper is closed with a green cover. For opera-

tion, the green cover is removed and the mixing tube is at-

tached to the mixing tube holder with two eccentric locks.

The mixing shaft is pushed into the mixing tube together

with the mixing tube cover and is also fastened to the mix-

ing tube frame with two eccentric locks.

NOTE

Make sure that the mixing shaft is con-

nected to the metering shaft.

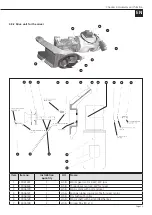

4.4.1.6 Drive unit for the feed pump, incl. chain gear

box and pump hopper

The pump motor is firmly connected to the chain gear box

and the pump hopper. The pump hopper contains the pump

shaft, which is connected to the pump unit (rotor/stator). A

level probe is also mounted in the pump hopper to monitor

the level of the material in the pump hopper.