Page 43

EN

Chapter 7 Commissioning

6.9 Starting the machine

1. For the use of bagged material you need a second man

who continuously fills the dry material into the material

hopper of the machine. When using one-way contain-

ers or big bag boxes, this second man is not needed.

2. As soon as the mixer has started up and the material

falls in the correct consistency through the mixing tube

opening into the pump hopper, the level probe installed

there measures the minimum and maximum level with

two probe rods. When the material reaches the upper

probe rod, the mixer is automatically switched off until

the material drops below the level of the lower probe

rod. Then the mixer is switched on again (automatic

mode).

3. The material is conveyed from the pump shaft to the

rotor/stator and from there further into the conveying

hose.

4. Check on the mortar pressure gauge whether the mor-

tar pressure is within the permissible pressure range.

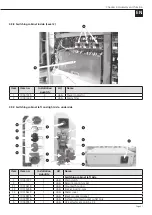

7 Commissioning

7.1 Adding material to the material hopper

Warning

Risk to health due to dust.

When cleaning the machine, inhaled dust can cause

long-term lung damage or other adverse health ef-

fects.

• The machine operator or people working in the dust area

must each wear a dust mask when cleaning the machine.

• Find out about the technical rules for hazardous sub-

stances (TRGS 559) “Mineral dust” on the homepage of

the German Social Accident Insurance Institution (www.

bgbau.de).

Warning

Risk of injury posed by powdery and paste-

like material

When filling the material container, swirling or splashing

material can cause injuries, especially in the area of the eyes

and face.

• Always wear safety goggles.

Warning

Observe the applicable work regulations

(e.g. respiratory protection)

7.2 Changing the material

1. Empty the material hopper and the pump hopper of the

inoCOMB Cabrio small silo.

2. Then switch off the machine.

3. Close the valve on the external water supply.

4. Clean the material container, the metering shaft and the

mixing tube with the mixing shaft. Also clean the pump

hopper with pump shaft and rotor/stator incl. the deliv-

ery hoses used.

!

WARNING

Operation without any material or with

too little material.

Danger of destroying the rotor/stator.

If the machine is operated without any material or with too

little material, there is a risk of the rotor/stator being de-

stroyed within an extremely short period of time (< 1 min.)!