5 Troubleshooting

5

- 50 -

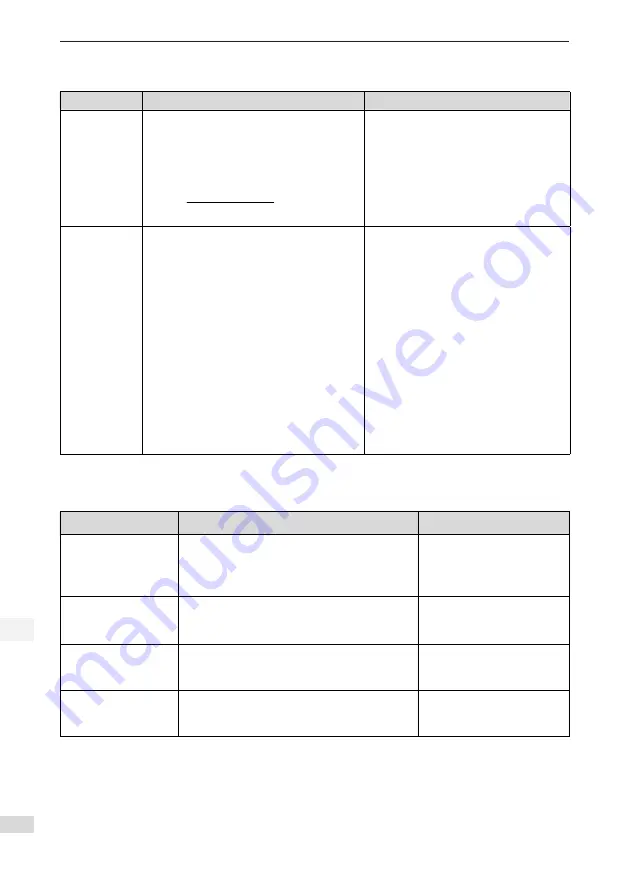

Er.510: Pulse output overspeed

Cause

Confirming Methods

Corrective Action

Output pulse

frequency

exceeds

frequency upper

limit allowed

by hardware (2

MHz).

When H05-38 = 0 (encoder frequency-division

output), calculate pulse frequency corresponding

to motor speed at occurrence of fault and check

whether the pulse frequency exceeds limit.

Output pulse frequency (Hz) =

Motor speed (rpm)

60

x H05-17

Decrease H05-17(Encoder frequency-

division pulses), making output pulse

frequency below frequency upper limit

allowed by hardware in the speed range

required by mechanical condition.

Output pulse

frequency

exceeds

frequency upper

limit allowed

by hardware (2

MHz).

When H05-38 = 1 (reference pulse synchronous

output), input pulse frequency exceeds 2 MHz or

interference exists on pulse input pin.

Low-speed pulse input pin:

Differential input terminals, PULSE+, PULSE-,

SIGN+, SIGN-

Max. pulse frequency: 500 kpps

Open-collector input terminals, PULLHI,

PULSE+, PULSE-, SIGN+, SIGN-

Max. pulse frequency: 200 kbps

High-speed pulse input pin:

Differential input terminals: ,

HPULSE-, HSIGN+, HSIGN-

Max. pulse frequency: 2 Mpps

Decrease input pulse frequency to within

frequency upper limit allowed by hardware.

In this case, if you do not modify electronic

gear ratio, motor speed will slow down.

If input pulse frequency is very high but is

still within frequency upper limit allowed by

hardware, take anti-interference measures

(use STP cable for pulse input and set pin

filter parameters H0A-24 or H0A-30), which

prevents interference pulse adding to pulse

and resulting in fault misreported.

Er.602: Angle auto-tuning failure

Er.610: Servo drive overload

Cause

Confirming Methods

Corrective Action

1. Parameter setting is

incorrect.

Check whether H01-02 (drive SN) is set correctly.

Check whether the gain parameters (group H08) or

the stiffness (H09-00 and H09-01) are set correctly.

Set H01-02 according to the

actual drive SN.

Adjust the parameters based

on the current feedback effect.

The servo drive load

ratio is too large (load

inertia excessive).

Check whether H0B-12 (average load ratio) is

excessive (over 80%) and then whether the inertia

is excessive through inertia auto-tuning.

Use a drive model of higher

power.

3. The servo drive

load ratio is too large

(mechanical stuck)

Check whether H0B-12 (average load ratio) is

excessive (over 80%) and then whether stuck

occurs during load running.

Eliminate the mechanical stuck

problem.

4. Locked rotor occurs

in the motor.

Check whether H0A-33 (locked rotor over-

temperature protection) is 0. If yes, the drive trips

Er.610 when locked rotor occurs.

Take actions for Er.630.

Summary of Contents for IS650P Series

Page 1: ......

Page 101: ...100 Revision History Date Version Change Description March 2017 A00 First issue...

Page 102: ......