1. Table of Contents

1.

Table of Contents

2. Generalities

2.1. Instructions manual .................................................................................................................................6

2.2. Compliance with the instructions ............................................................................................................6

2.3. Warranty..................................................................................................................................................6

3. Safety

3.1. Warning symbols.....................................................................................................................................7

3.2. General safety instructions .....................................................................................................................7

4. General Information

4.1. Description ..............................................................................................................................................9

4.2. Application ...............................................................................................................................................9

5. Installation

5.1. Reception of the valve ..........................................................................................................................10

5.2. Transport and storage ...........................................................................................................................10

5.3. Identification of the valve

......................................................................................................................10

5.4. Location ................................................................................................................................................12

5.6. Direction of flow

....................................................................................................................................12

5.5. General installation ...............................................................................................................................12

5.7. Checking and review .............................................................................................................................13

5.8. Welding .................................................................................................................................................13

5.9. Valve configuration with actuator

..........................................................................................................14

5.10. Connecting the air to actuator .............................................................................................................14

6. Start-up

7. Operating problems

8. Maintenance

8.1. General considerations .........................................................................................................................17

8.2. Maintenance .........................................................................................................................................17

8.3. Cleaning ................................................................................................................................................18

8.4. Disassembly and assembly the valve ...................................................................................................20

8.5. Replacing the seat seal .........................................................................................................................22

8.6. Actuator configuration

...........................................................................................................................23

9. Technical Specifications

9.1. Valve

9.2. Actuator .................................................................................................................................................24

9.3. Materials ...............................................................................................................................................24

9.4. Sizes available ......................................................................................................................................24

9.5. Weights of the INNOVA Mini N and INNOVA Mini K valve ...................................................................25

9.6. Dimensions of the INNOVA Mini N and INNOVA Mini K valve ..............................................................25

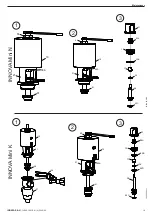

9.7. Exploded drawing and parts list of the INNOVA Mini N valve ...............................................................26

9.8. Exploded drawing and parts list of the INNOVA Mini K valve ...............................................................27