2015/01

8.Technical Specifications

17

8.

Technical Specifications

8.1.

TECHNICAL SPECIFICATIONS

Maximum operating pressure

1000 kPa (10 bar)

Temperature range

-10 to 120 °C (EPDM)

Maximum speed

3000 rpm (50 Hz)

3600 rpm (60 Hz)

Materials

Parts in contact with the product

AISI 316L (1.4404)

Other steel parts

AISI 304L (1.4306)

Gaskets in contact with the product

EPDM (standard)

FPM (other materials available upon request)

Other gaskets

EPDM

Exterior surface finish

Bright polished

Interior surface finish

Polished Ra<0,8

μ

m

Mechanical seal

Type

Single internal seal

Material of rotating part

Graphite (C) (standard)

Silicon carbide (SiC)

Material stationary part

Silicon carbide (SiC) (standard)

Gasket material

EPDM (standard)

FPM

Motor

Type

Three-phase asynchronous motor, IEC B34 type, 2 or 4 poles, IP55

protection, Class-F insulation

Power

0.37 to 11 kW

Voltage and frequency

220-

240 V Δ / 380

-420 V

Υ, ≤ 4 kW

380-

420 V Δ / 660

-

690 V Υ,

≥

5.5 kW

8.2.

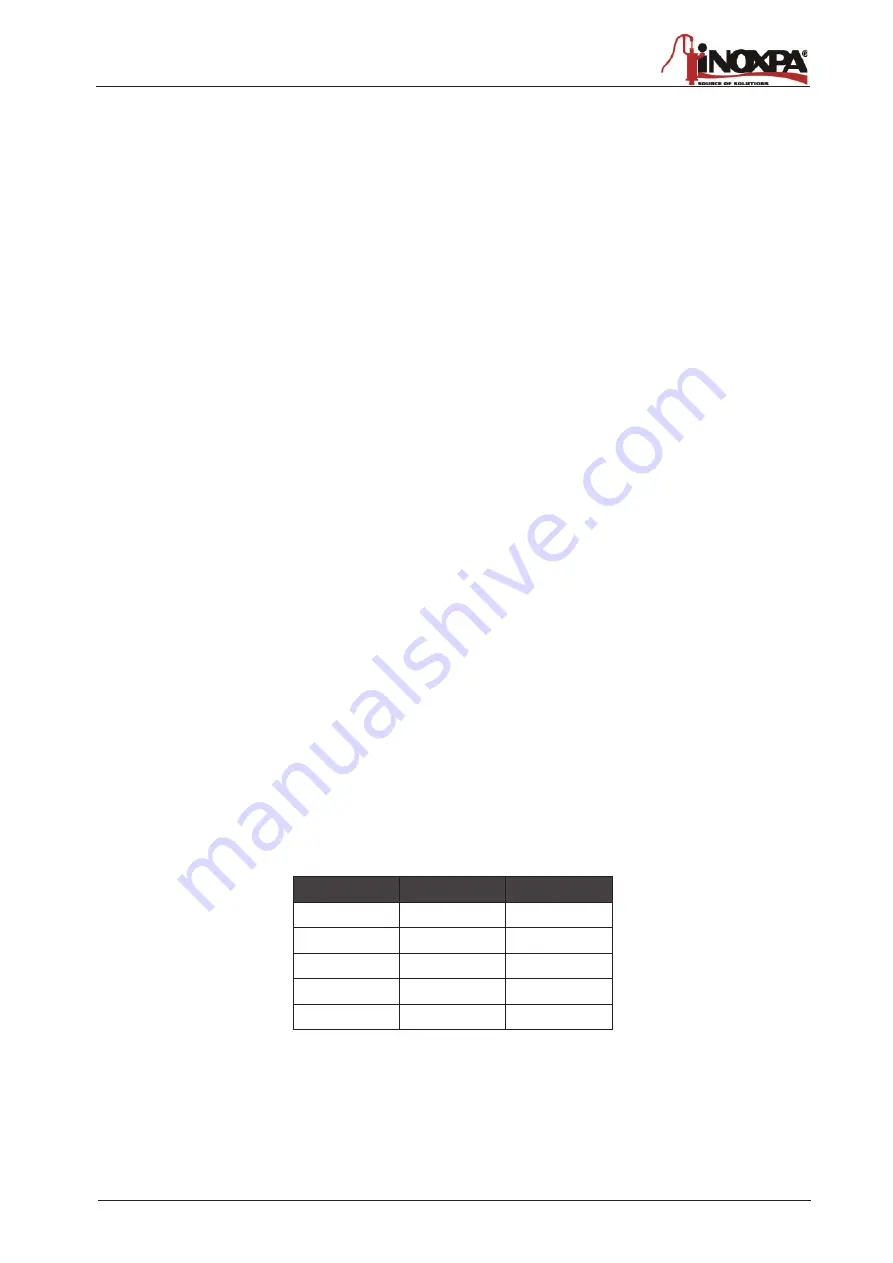

TIGHTENING TORQUES

If not stated otherwise, the torques listed in the following table should be applied on the nuts and bolts of this pump.

Size

Nm

lbf·ft

M6

10

7

M8

21

16

M10

42

31

M12

74

55

M16

112

83