www.insigniarange.com

Last Modified: 25/07/2019

21

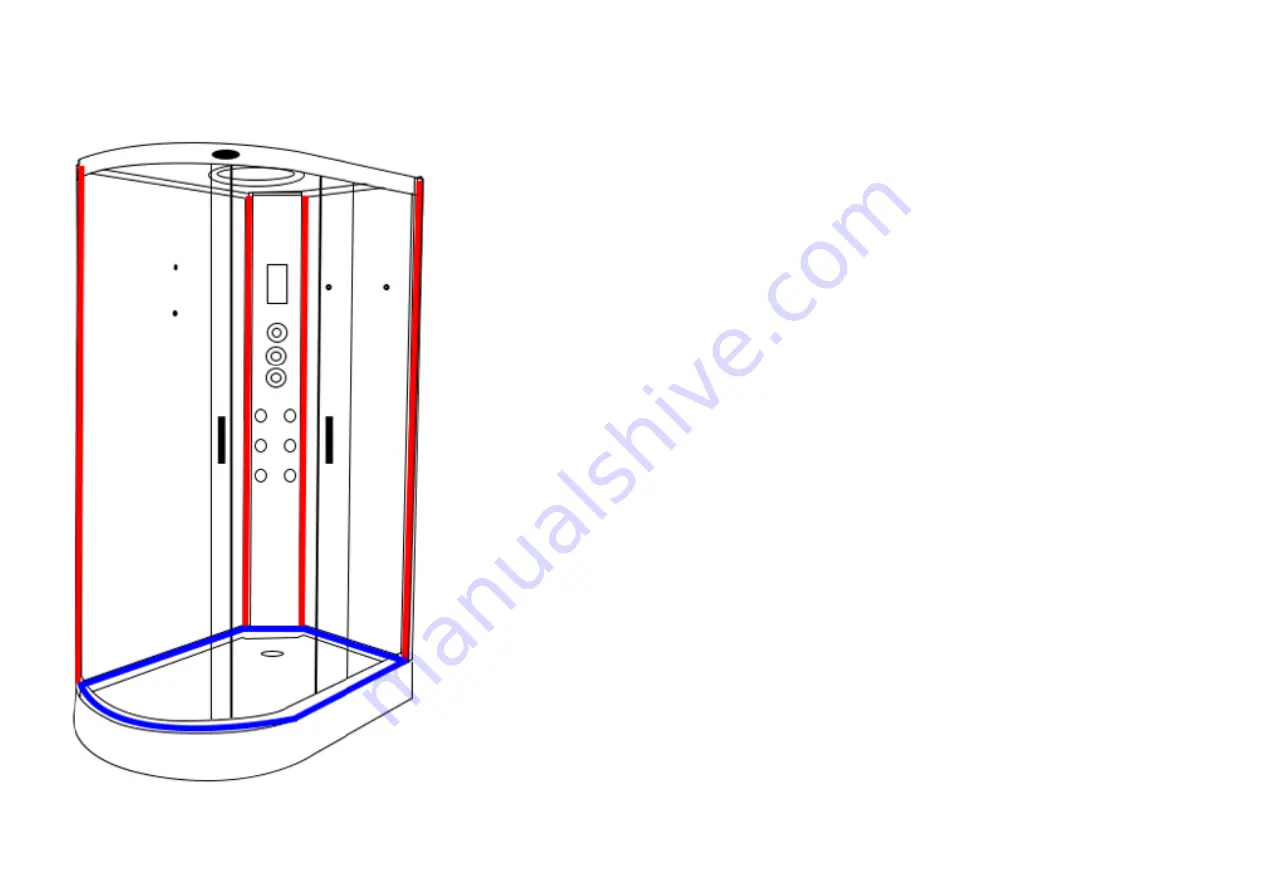

Silicone Seal (vertical joints)

-

RubberGum (horizontal joints)

TESTING FOR WATER LEAKS

LEAVE THE SHOWER 24 HOURS AFTER BUILD TO ALLOW SEALANT TO CURE AND ENSURE

THE SHOWER IS AWAY FROM ITS FINAL POSITION TO ALLOW REAR VIEWING

Ensure all connections are tight and sealed including the waste, body jets and steam outlet (model

dependent) on your shower.

We also advise to run a thin bead of silicone around the control panel.

Switch on the overhead shower NOT the massage jets, remember these will fire water out at you and

are not suitable for checking leaks as they would normally only operate when a person is in front of

them. DO NOT AIM THE HAND SHOWER AT THE JOINTS OF YOUR SHOWER AS THIS DOES

NOT FALL UNDER

“

NORMAL EVERYDAY USE

”.

Adjust the feet to ensure the direction of the water

flows towards to the waste to prevent puddling.

Just use COLD water setting as hot will make cabin misty and condensate thus the inspection

becomes very difficult. Now on the OUTSIDE of the shower inspect each joint, factory seal, hose, clip

and jet by walking from one side and going around to the back and then to the other side finishing at

the front. If you have a small leak (normally caused through insufficient sealer or air bubble on

assembly, dry the area thoroughly and reseal.

Please remember the location of the water may not be exactly where the leak is as it could have run

around to a low point. Never seal your inner fittings unless necessary, remember you will see this for

the life of the shower! Again leave to cure and check. Once you are happy check the shower functions

i.e. jets for back massage, foot massage and finally hand shower (model dependent) check your joints

to these functions at the rear again. Never use the shower until

all

checks have been made and the

installer is 100% happy in the knowledge no leaks are present.

Important Note:

It is not uncommon due to temperature changes, glass seals fitted into the frame

lower horizontal and sides can and do shrink leaving a small gap. This is normal to prevent rubbers

perishing or opening later in your showers life. Check yours now, any slight gaps simply seal neatly

with a thin bead of silicone. This will prevent chances of leakage both now or later in life.

All good?

Now push your shower FROM THE BASE and NEVER THE GLASS OR FRAME into its final resting

position.

Happy Showering!