6

DRAIN LINE CONNECTIONS

DRAIN LINE CONNECTIONS

DRAIN LINE CONNECTIONS

DRAIN LINE CONNECTIONS

DRAIN LINE CONNECTIONS

To allow easy access to overload reset button, the

disposer plumbing should be connected with the

electrical control box facing the operator.

When connecting the drain line, place the “P-trap” as

close to the disposer outlet flange as possible. Do not

connect the drain line to a grease trap, interceptor, or

drum trap.

All horizontal runs should be as short as possible, with

a minimum fall of 1/4 inch per foot.

ROUTING WATER FLOW

ROUTING WATER FLOW

ROUTING WATER FLOW

ROUTING WATER FLOW

ROUTING WATER FLOW

• In a trough system

trough system

trough system

trough system

trough system, route all water flow to the end of

the trough to flush food waste.

• In an sink bowl

sink bowl

sink bowl

sink bowl

sink bowl system with an SS-50

SS-50

SS-50

SS-50

SS-50 to SS-125

SS-125

SS-125

SS-125

SS-125 (3-5

GPM), , , , , route all water through the sink bowl (see

Table 2).

• In a sink bowl

sink bowl

sink bowl

sink bowl

sink bowl system with an SS-150

SS-150

SS-150

SS-150

SS-150 to SS-1000

SS-1000

SS-1000

SS-1000

SS-1000 (7-

10 GPM), route water through the sink bowl

and the

disposer body inlet.

PLUMBING

PLUMBING

PLUMBING

PLUMBING

PLUMBING

Property Damage

These plumbing instructions were written for an experi-

enced and competent installer. If the installer is not expe-

rienced in plumbing installation, ISE recommends that com-

petent professional assistance is sought. Damage to the

disposer or accessories as a result of improper installa-

tion is not covered under warranty. All installations must

comply with local plumbing codes.

DRAIN LINE CONNECTIONS

DRAIN LINE CONNECTIONS

DRAIN LINE CONNECTIONS

DRAIN LINE CONNECTIONS

DRAIN LINE CONNECTIONS

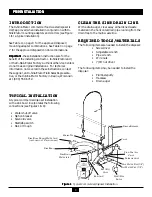

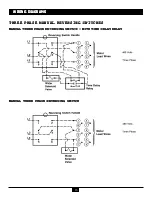

Figure 9:

Figure 9:

Figure 9:

Figure 9:

Figure 9:

Water & Electrical Connections

F

LOW

C

ONTROL

V

ALVE

W

ATER

S

OLENOID

V

ALVE

W

ATER

S

UPPLY

D

ISPOSER

S

INK

W

ATER

I

NLET

C

ONNECTION

(

OPTIONAL

)

1/2 NPT

S

IPHON

B

REAKER

S

TART

/S

TOP

S

WITCH

E

LECTRICAL

S

UPPLY

WATER SUPPLY CONNECTIONS

WATER SUPPLY CONNECTIONS

WATER SUPPLY CONNECTIONS

WATER SUPPLY CONNECTIONS

WATER SUPPLY CONNECTIONS

When connecting the disposer to the incoming water

supply, use as few elbows and tees as possible. (Con-

nect to the cold

cold

cold

cold

cold water line only.) All water line fittings

are 1/2” NPT except the sink bowl nozzles (1/2”

compression).

Install the flow control valve, water solenoid valve, and

the siphon breaker according to the direction of the

flow arrows marked on each valve body (see Figure 9).

NOTE:

NOTE:

NOTE:

NOTE:

NOTE: A siphon breaker must be installed above the

sink flood plane per local plumbing codes.

Disposer

Water Flow

Drain Line

GPM (LPM)

Diameter

SS-50

3 (11)

1 1/2"

SS-75

3 (11)

1 1/2"

SS-100

5 (19)

1 1/2"

SS-125

5 (19)

1 1/2"

SS-150

7 (26)

2" NPT

SS-200

7 (26)

2" NPT

SS-300

8 (30)

3" NPT

SS-500

8 (30)

3" NPT

SS-750

10 (38)

3" NPT

SS-1000

10 (38)

3" NPT

GPM = Gallons Per Minute NPT = National Pipe Thread

LPM = Liters Per Minute

Table 2:

Table 2:

Table 2:

Table 2:

Table 2:

Recommended Cold Water Flow & Drain

Line Diameter

▲

▲

▲

Summary of Contents for 13954

Page 1: ......