7

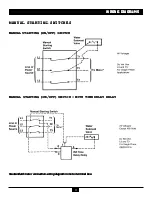

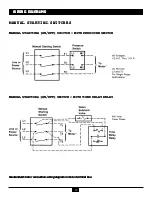

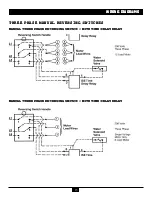

Model Phase

AS101

Manual

Magnetic

Manual

CC101 CC202

Start Switch

Starter Switch

Reverse Switch

SS-50

1

X

X

X

X

X

X

SS-50

3

X

X

X

X

X

X

SS-75

1

X

X

X

X

X

X

SS-75

3

X

X

X

X

X

X

SS-100

1

X

X

X

X

X

X

SS-100

3

X

X

X

X

X

X

SS-125

1

X

X

X

X

X

X

SS-125

3

X

X

X

X

X

X

SS-150

1

X

X

X

X

X

X

SS-150

3

X

X

X

X

X

X

SS-200

1

X

X

X

X

X

X

SS-200

3

X

X

X

X

X

X

SS-300

3

X

O

X

X

X

X

SS-500

3

X

O

X

X

X

X

SS-750

3

X

O

O

O

X

X

SS-1000

3

X

O

O

O

X

X

X = Approved

O = Not Approved

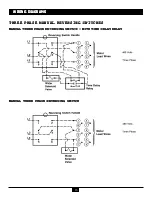

Table 3:

Table 3:

Table 3:

Table 3:

Table 3:

Approved Disposer/Control Combinations

ELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONS

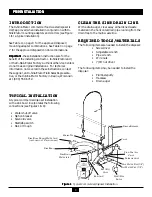

To connect the disposer to the electricity:

1 . Remove the screw in the center of the disposer

terminal box.

2. Pull the terminal box out of the stainless-steel trim

shell.

3. Connect an electrical conduit connector to the hole

in the bottom of the exposed wiring compartment.

4. Connect the ground wire to the ground screw.

5. Connect the incoming wires to the motor leads.

(Make sure the wiring connections are the same as

those on the motor control wiring diagram for your

specific control.) (See pages 10 - 17.)

6. Reinstall the terminal box cover on the trim shell.

NOTE:

NOTE:

NOTE:

NOTE:

NOTE: Complete electrical information is located

inside the disposer terminal box.

7. Test the disposer to ensure that the cutting elements

revolve and the water flows automatically. Make

sure the disposer is securely mounted and does not

leak from any of the connections.

ELECTRICAL SAFETY

ELECTRICAL SAFETY

ELECTRICAL SAFETY

ELECTRICAL SAFETY

ELECTRICAL SAFETY

ELECTRICAL

ELECTRICAL

ELECTRICAL

ELECTRICAL

ELECTRICAL

Electrical Shock

• Turn off the electrical supply to the disposer before ser-

vicing. (Test the circuit with a volt meter or circuit tester

to ensure the power is off.)

• All control centers and disposers must be grounded.

• A properly fused disposer control (with a marked “off”

position) that disconnects all ungrounded supply con-

ductors must be installed at the electrical supply source.

Personal Injury/Property Damage

If the electrical installer is not experienced in electrical in-

stallation, we recommend seeking competent professional

assistance. Disposer or accessory damage due to im-

proper installation is not covered under warranty. All in-

stallations must comply with local electrical codes.

Property Damage

• Disposers shipped from the factory are not wired for a

specific voltage. Refer to the motor connection wiring

diagram in the terminal box for voltage instructions.

• Ensure that the disposer motor voltage and phase match

that of the electrical supply.

DISPOSER CONTROLS

DISPOSER CONTROLS

DISPOSER CONTROLS

DISPOSER CONTROLS

DISPOSER CONTROLS

Install the disposer controls within sight of the disposer (per local codes) so the disposer can be reached easily in an

emergency situation. In-Sink-Erator approved disposer/control combinations are listed in Table 3.

Electric Shock

Be careful not to pinch or damage the electrical wires when

replacing the terminal box.

Summary of Contents for 13954

Page 1: ......