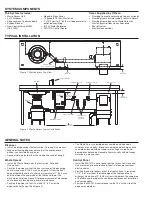

Trough Flow

Water Nozzle

Recommended

Magnet Location

Optional Magnet Location

Connect Cold Water Supply

1" min

(25.4 mm min)

1" (25.4 mm) min,

3" (76.2 mm) max

to end of Trough

PLUMBING NOTES

Fresh Water Connections

• 1/2" (12.7 mm) NPT – used on syphon breaker, solenoid and

flow control valve.

• 1/2" (12.7 mm) NOM compression – used on sink bowl nozzles.

• 1/2" (12.7 mm) Ridged Copper (compression) – used on hot

water connection to pulper.

• If fresh water supply is greater than 50 psi (144.7 kPa), a

pressure regulating valve must be installed in both.

• It is recommend that ball type shutoff valves be installed

in the cold and hot water lines.

• It is recommended that the hot water connected between

solenoid valve and pulper be terminated with a union for

ease of serviceability.

Waste Connection

• 2" (50.8 mm) NPT – used between disposer, Waste Xpress

and drain

• When connecting the drain line from the disposer to the

Waste Xpress use a maximum of (4) 90° bends (45° bends

are recommended) with a 1/4" (6.4 mm) drop per foot of run

or as local codes apply.

• Floor sink or drains should be installed per local codes but

kept clear of yet accessible to pulper.

• Trough applications in excess of 10' (3.1 m) and/or systems

plumbed with a cold water supply greater than 7 GPM

(26.5 LPM) must incorporate the second drain outlet from the

pulper and be drained independently to floor sink or drain.

TROUGH APPLICATION NOTES

Magnet

• Can be mounted to trough either by tack welding to using weld

studs (see instruction sheet for weld stud pattern).

• Trough magnets should be placed within 12" (304.8 mm) of

end of trough or trough intersection with sink bowl (see Figure 4).

• Additional magnets can be used as necessary.

Construction

• The recommended maximum trough length is 10' (3.1 m).

• A silver saver should be fabricated prior to end of trough to

catch utensils and dishes.

Water Supply

• For trough lengths of 10' (3.1 m) or less place water nozzle at

end of trough.

• For trough lengths greater than 10' (3.1 m) place one

water nozzle at end of trough and one mid stream.

• Do not plumb water to disposer grind chamber.

Figure 4. Trough Typical Installation

Figure 3. Trough Typical Installation Top View