Model Number:

Electrical

Requirements:

Item Number:

Quantity:

Manufacturer:

PROJECT INFORMATION

InSinkErator

volts phase

Project:

Address:

City/State/Zip:

Contact:

Phone:

Dealer:

City/State/Zip:

Contact:

Phone:

Installer:

Contact:

Phone:

Consultant:

Contact:

Phone:

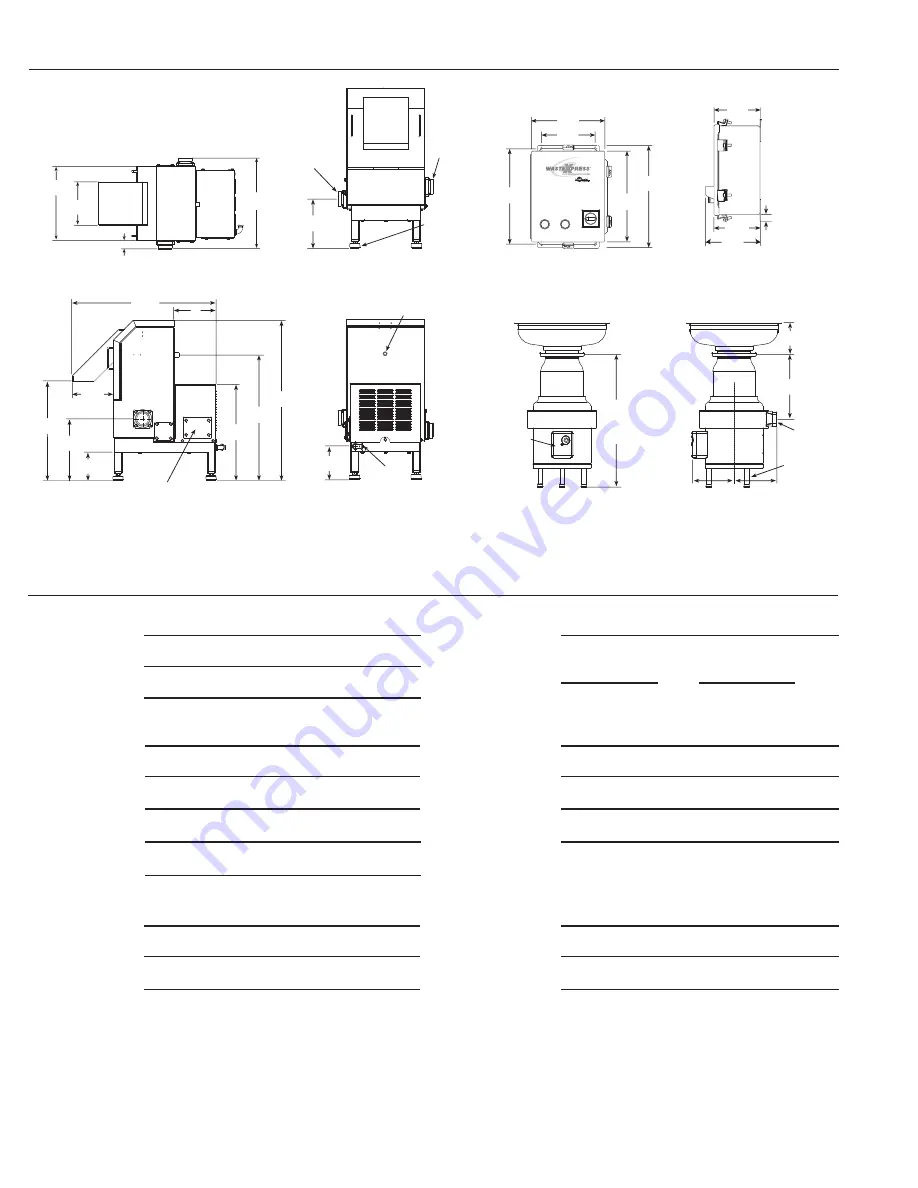

21-3/4"

(552.5 mm)

21-1/8"

(536.6 mm)

26-7/8"

(682.6 mm)

33-1/2"

(850.9 mm)

8"

(203.2 mm)

27-3/8"

(695.3 mm)

7-7/8"

(200.0 mm)

Electrical Connection Cover

14-1/2"

(368.3 mm)

8-1/8"

(206.4 mm)

15"

(381 mm)

18-3/4"

(476.3 mm)

1-5/8"

(41.3 mm)

Waste Xpress Top View

15-1/8"

(384.2 mm)

14"

(355.6 mm)

15-3/4"

(400.1 mm)

9-7/8"

(250.8 mm)

8-1/4"

(209.6 mm)

Control Center Front View

Waste Xpress Side View

9-1/8"

(231.8 mm)

1/2"

(12.7 mm)

Electrical Inlet

1/2"

(12.7 mm)

Hot Water Inlet

Waste Xpress Back View

12-1/8"

(308.0 mm)

2"

(50.8 mm)

NPT Outlet

(Either Side)

2"

(50.8 mm)

NPT Inlet

(Either Side)

Leveling Foot

Adjustment Range

2-3/4"

(69.9 mm)

Waste Xpress Front View

8-5/8"

(219.1 mm)

Disposer Front View

External Electrical

Connection Cover

2"

(50.8 mm)

NPT Outlet

Adjustable Legs

Disposer Side View

8-3/4"

(222.3 mm)

8-3/4"

(222.3 mm)

13"

(330.2 mm)

23-3/4"

TO

31-1/8"

(603.3 mm

TO

790.6 mm)

6-1/2"

(165.1 mm)

Control Center Side View

5-1/4"

(133.4 mm)

5-5/16"

(134.9 mm)

6-3/4"

(171.5 mm)

1"

(25.4 mm)

DIMENSIONS