Page 4

2.

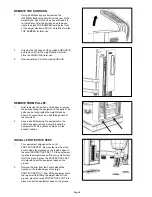

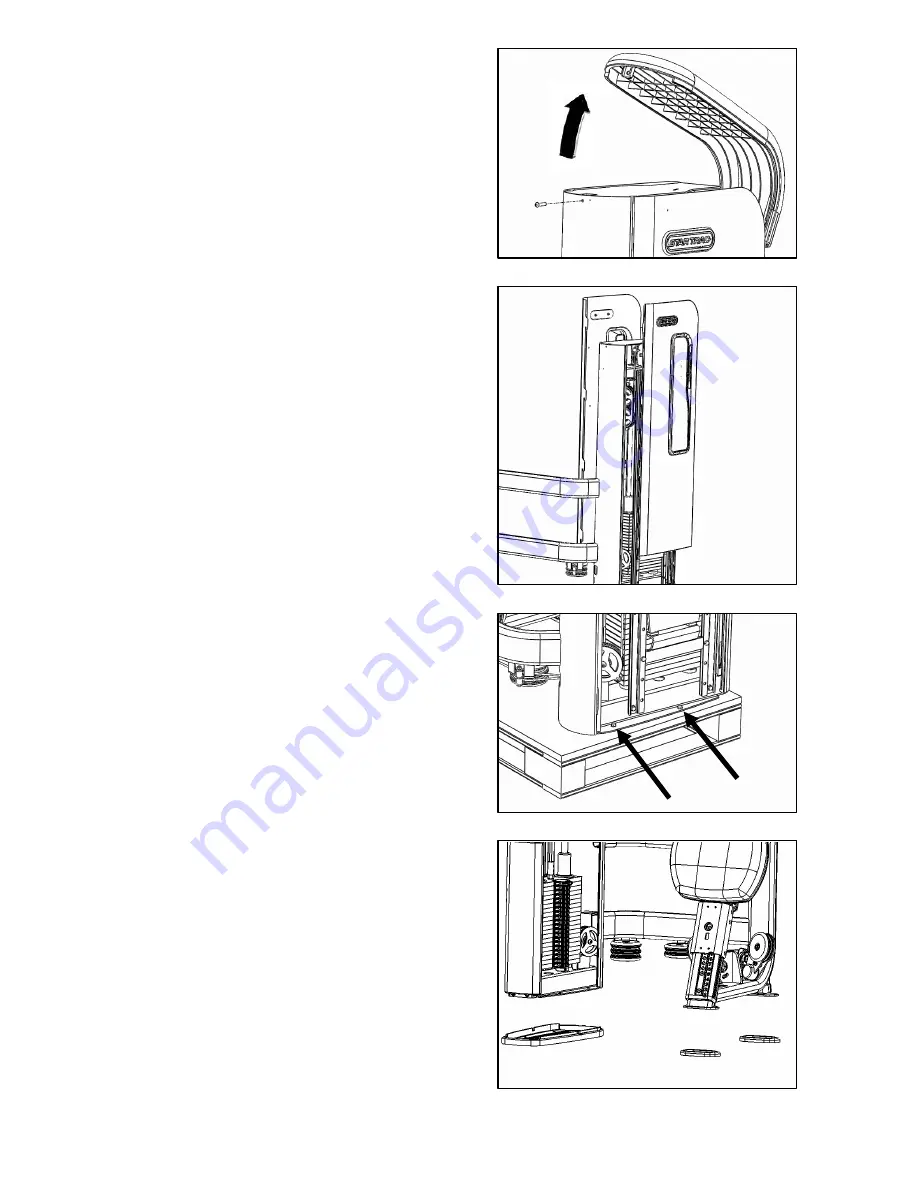

Gripping the top edges of the outside SHROUD lift

and remove it from the weight stack. Carefully

store the SHROUD for later use.

3.

Now repeat step 2 with the inside SHROUD.

REMOVE THE SHROUDS:

1.

Using a 4MM hex key socket remove the

(M6,30MM,Button Head Bolt) from the rear of the

weight stack. Save this bolt as you will need it to

re-install later. After the bolt has been removed

rotate the black TOP BUMPER towards the front

of the weight stack and lift it off. Carefully store the

TOP BUMPER for later use.

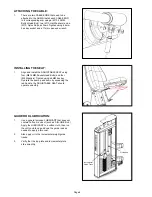

REMOVE FROM PALLET:

1.

After removing the shrouds, listed above, remove

the bolts securing the equipment to the pallet. The

bolts can be found inside the weight stack as

shown. There will also be a bolt through each of

the small feet.

2.

Once all bolts fastening the equipment to the

pallet have been removed, carefully slide the

equipment off of the pallet and place it in the

desired location.

INSTALL PROTECTIVE FEET:

1.

Your equipment shipped with a set of

PROTECTIVE FEET. Remove the liner from the

double sided tape located on the inside edges of

the small PROTECTIVE FEET. Tilt the equipment

towards the weight stack until the two smaller feet

lift off the ground, press the PROTECTIVE FEET

into place and set the equipment back on the

ground.

2.

Remove the liner from the double sided tape

located on the inside edges of the large

PROTECTIVE FOOT. Now tilt the equipment onto

the two small feet lifting the weight stack off the

ground, press the large PROTECTIVE FOOT into

place and set the equipment back on the ground.

Summary of Contents for IP-S4305

Page 1: ...SHOULDER PRESS IP S4305 INSTALLATION INSTRUCTIONS...

Page 9: ...Page 9...