Page 7

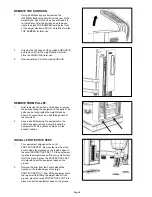

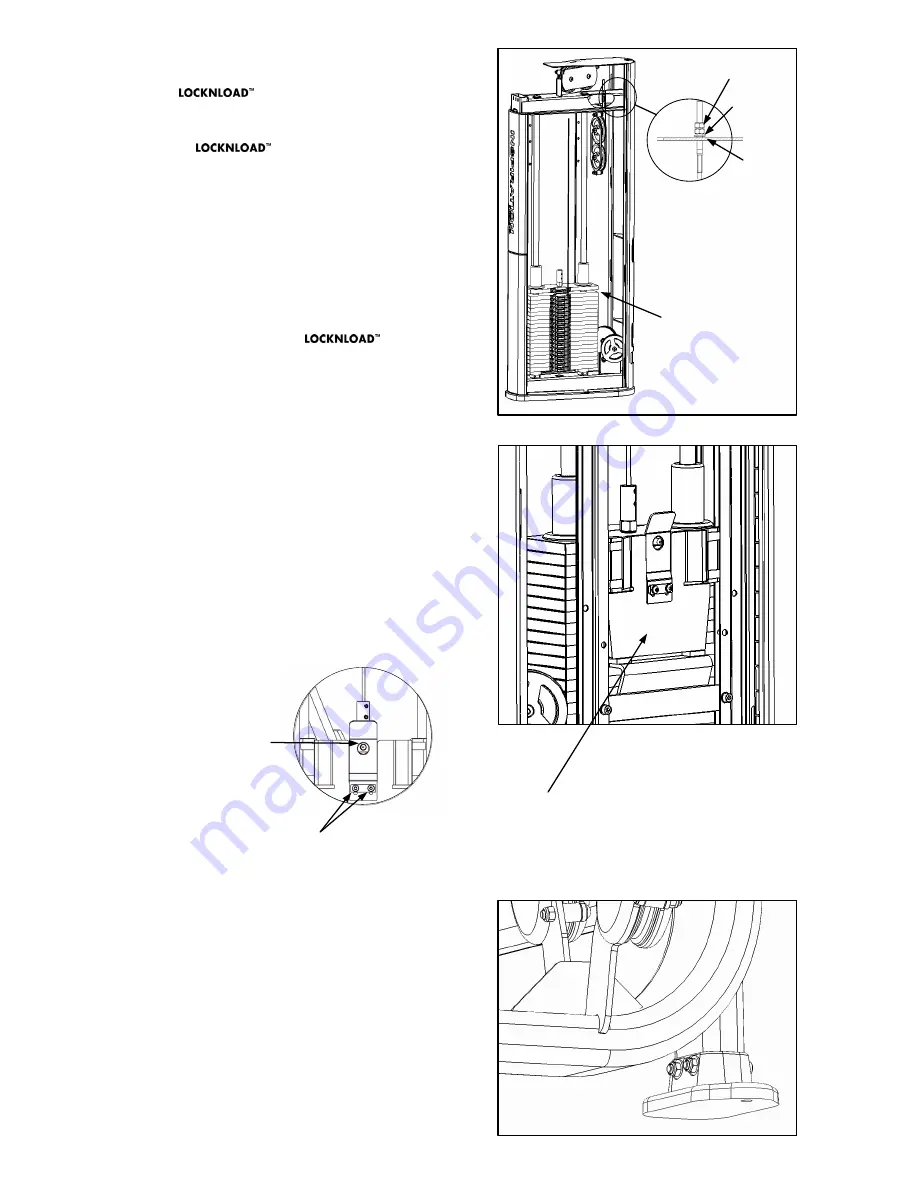

M8 Jam Nut (2X)

Frame

No Gap

Washer (2X)

GAP

SCREWS

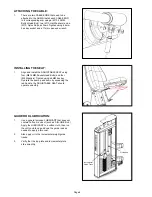

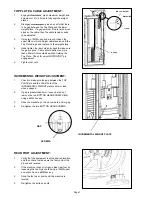

INCREMENTAL WEIGHT ADJUSTMENT:

1.

Check to make sure the gap between the TOP

PLATE pin and the 20mm hole of the

INCREMENTAL WEIGHT plate is 3mm or less

when engaged.

2.

If gap is greater than 3mm, loosen but do not

remove the two BUTTON HEAD SCREWS (M6)

using a 4MM hex key.

3.

Slide the bracket up or down to create a 3mm gap.

4.

Re-tighten the two BUTTON HEAD SCREWS.

INCREMENTAL WEIGHT PLATE

REAR FOOT ADJUSTMENT:

1.

Verify that the equipment is at the desired location

and then check to make sure the feet contact the

ground and leveled.

2.

If the machine rocks or is tippy, adjust rear foot by

loosening the two Nyloc nuts using a 13MM open-

end wrench and a 6MM hex key.

3.

Slide the foot up or down until the machine is

leveled.

4.

Re-tighten the bolts and nuts.

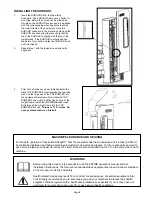

TOP PLATE & CABLE ADJUSTMENT:

1.

Engage pin at maximum weight and

actuate arm 3 to 4 times to fully seat the weight

stacks.

2.

Disengage pins and verify that there

is no gap between the Top Plate and the lower

weight plate. If a gap exists or if there is too much

slack on the cable, then the cable tension needs

to be adjusted.

3.

Using two 13MM open end wrench, loosen the

upper M8 Jam Nuts. Adjust cable tension until the

Top Plate drops and rests on to the weight stack.

4.

Hand tighten the jam nuts and check to make sure

the gap is gone. Cable should deflect no more

than ±25mm from centerline without raising the

Top Plate. Check for smooth pin

engagement.

5.

Tighten jam nuts.

Summary of Contents for IP-S4305

Page 1: ...SHOULDER PRESS IP S4305 INSTALLATION INSTRUCTIONS...

Page 9: ...Page 9...