Page 5 of 38

SPAN 500 BRIDGED TOWER

•

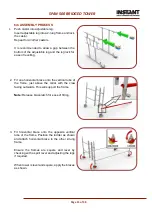

We recommend a minimum of three people to assemble, dismantle and move the platform tower.

•

Check that all components are on site and in good working order.

•

Ensure that the assembly location is checked to prevent hazards during assembly, dismantling or moving

and while working on the tower. Particular attention should be given to the ground condition, whether level

or sloping, obstructions and wind conditions. The ground condition must be capable of supporting the tower

structure.

•

Towers must always be climbed from the inside of the assembly using the ladder.

•

Adjustable legs must only be used to level the tower and leg extension must be minimized before the

tower is moved (max 150mm).

•

Lifting of components must be done inside the effective base area of the tower; components are normally

hoisted using a rope.

•

Moving the tower must only be done by manual effect from the base of the tower.

•

When moving tower be aware of overhead hazards (e.g. electric cables).

•

No personnel or material to be on the platform whilst the tower is being moved.

•

When tying-in the tower, attach a tie to each upright at 4m height intervals. Ensure that couplers are

suitable for 50mm diameter aluminium tube.

•

Do not use boxes or steps to gain additional height. If extra height required, contact your distributor to

get extra components.

•

Do not lift or suspend an assembled mobile tower.

•

Damaged components or components from other tower systems must never be used.

•

Stabilisers should always be fitted when specified. Use the stabiliser shown on the component list

according to the tower height.

•

When wind exceeds Beaufort force 4, cease using the tower.

•

If wind is expected to reach Beaufort force 6, tie tower to a rigid structure.

•

If winds of Force 8 are forecast, dismantle the tower or remove to shelter.

•

Wind speed should not exceed 29km/h (8.1m/s)

•

Ensure leg extension is minimised (Max 150mm). Release the castor brakes.

•

Raise the stabiliser feet only enough to clear obstructions, maximum 25mm.

•

Ensure tower is empty (material and personnel).

•

Check for overhead obstructions including electrical wires.

•

Move the tower manually by applying force at the base

– do not use machinery to push or pull the tower.

Once moved

– prepare the tower for use, use the pre-use safety inspection checklist at the end of this

manual.

•

Check all castors and stabilisers are in firm contact with the ground.

•

Check tower is vertical (spirit level) and adjust legs as required.

•

Reapply the castor brakes.

USAGE ADVICE

MOVING TOWERS