Page 7 of 38

SPAN 500 BRIDGED TOWER

ANCHORS, TIES & BALLAST

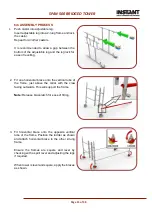

This tower has been designed to be self-supporting under the loading conditions set out in EN1004:2005 and

does not require tying in. Tying in should be considered for potential wind conditions if the tower is left

unattended. When used, selected and installed anchors in concrete and masonry must be selected and

installed in accordance with BS8539. This prefabricated tower scaffold has been designed to be properly

secured to a suitable adjacent supporting structure capable of withstanding the forces that will be imposed

upon it by the attachment of the tower. Devices for securing the tower must be simultaneously rigid in both

tension and compression and capable of withstanding and transmitting the loads imposed by the tower to the

supporting structure.

If ballast is necessary, it must be secured in position and made of rigid material such as steel or concrete but

excluding liquid or granular material.

•

Tower must be built on base plates and properly secured to an adjacent supporting structure to prevent

movement of the tower away from the structure at the point of access.

•

There must be no gaps between the platform of the scaffold tower and the place being accessed through

which a person, tools or materials could fall.

•

The platform of the scaffold tower and the surface onto which a person will step when accessing another

place must be at the same level.

•

Means of protection must be removed only for the time and to the extent necessary to gain access or egress

or for the performance of a task and must be replaces as soon as practicable.

•

The task must not be performed while means of protection are removed unless effective compensatory

measures are in place.

•

Provision must be made to prevent falls

– not only from the prefabricated tower scaffold, but also from the

adjacent structure.

CARE AND MAINTENANCE

•

Keep all equipment clean, especially spigots and sockets where frames join. Spigots should fit easily into

sockets. Lubricate with light oil.

•

Remove dirt or paint from adjustable legs with a light brush, lightly oil the leg locks.

•

Do not strike or hammer components. Do not throw or drop onto hard surfaces.

•

Lightly oil spring mechanism of the hooks.

•

For transport and storage, components are best stored vertically.

•

Damaged parts should be repaired or replaced. Contact your equipment supplier for advice.

•

Ensure parts are not damaged by excessive strapping forces when transported.

•

Refer to the Instant Upright website for a detailed inspection guide: www.instantupright.com

USE OF PREFABRICARTICATED SCAFFOLDS FOR ACCESS TO ADJACENT STRUCTURES