© Intatec Ltd 2009

2

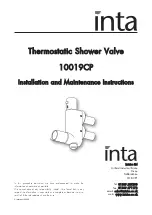

Installation Instructions

Stud Wall

Installation with the supply pipes concealed behind

a stud wall.

Cut 2 holes 24 to 26mm in diameter at 45mm

centres in the plaster board or wall plate.

Finish tiling the wall cutting 2 holes 24mm to 26mm

in the tiles.

Insert the shower valve through the two holes and

secure with the 2 back nuts, do not over tighten.

Connect the hot supply to the lower inlet and the

cold to the upper.

A swivel to copper connector or an olive and

compression nut are 2 typical fittings for making the

connections.

Connect the flexible hose of the shower kit to the mixed

water outlet and secure the rail to the wall.

Turn on the water supplies and check joints for leakage.

Solid Wall

Installation with the supply pipes embedded into a solid wall.

Cut a channel into the wall for the supply pipes allowing

sufficient depth to position the concealing plates to as shown

on the finished tiled surface.

Connect the supply pipes to the valve and turn of the water

supplies and check for leakage from any joints.

Turn off the water supplies.

Unscrew the two socket set screws and carefully remove the

body and concealing plates.

Fill the channel and finish tiling the wall.

Seal the holes between inlets and tiles with silicone

sealer.

Refit the concealing plates and push firmly to the wall

surface.

Carefully refit the valve and re-tighten the socket set

screws.

Connect the flexible hose of the shower kit to the mixed

water outlet and secure the rail to the wall.

Turn on the water supplies and check for correct

operation.

Plaster board

and tiled wall

Swivel

connector

Olive and

comp. nut

Socket

set screw

Concealing

plate

Mixed water

outlet

82

40

145

45

Ctr

5

G

1/2

B

G

1

/

2

B

G

1

/

2

B

Cold Inlet

Hot Inlet

19.5