© Intatec Ltd 2009

3

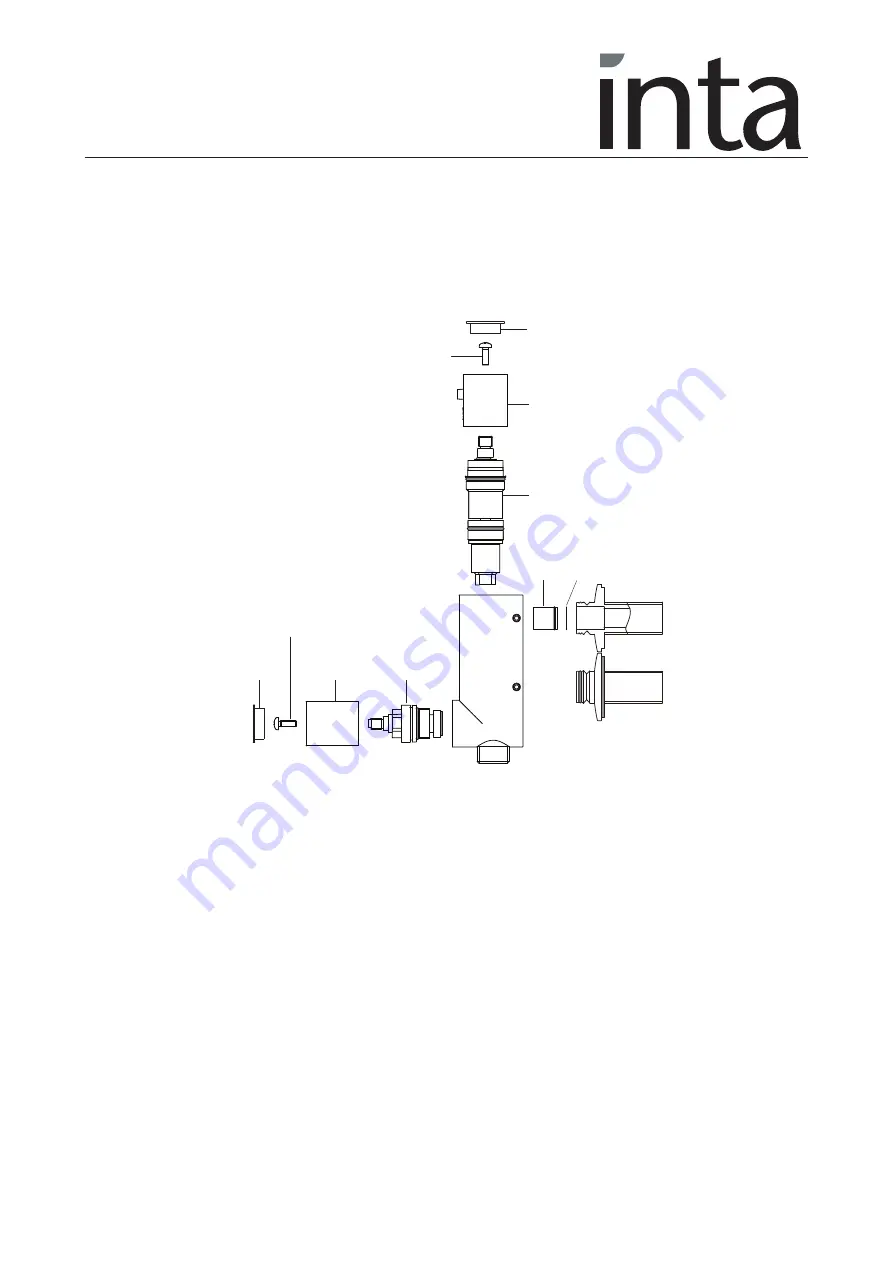

Flow Control Valve Replacement

Isolate both the hot and cold water supplies

Remove the cover and unscrew the control knob retaining screw and remove the flow control knob.

Using a suitable spanner unscrew the flow control valve.

Replace with a new valve or replace the disk washer as required and assemble in the reverse order.

Cartridge Replacement

Isolate both the hot and cold water supplies.

Remove the cover and unscrew the control knob retaining screw and remove the temperature control knob.

Carefully pull the cartridge out of the body

If any of the ‘O’ ring seals or the thermostatic element is blocked or damaged they must be replaced.

Using neutral silicon grease re-lubricate the internal moving components of the valve.

Re-assemble in the reverse order.

The valve must then be re-commissioned following the procedure detailed.

Operation

The red button on the temperature control knob locks the mixed water temperature to 38˚C, press the

button to release the knob to increase the or lower the water temperature.

Turning the flow control knob anti-clockwise turns on the water and regulates the amount flowing.

Components

Cover

Retaining

screw

Flow control

valve

Control

knob

Cover

Retaining

screw

Temperature

control knob

Thermostatic

cartridge

Filter

Non turn

valve