© Intatec Ltd 2009

4

Filter Cleaning and Non Return Valve Removal

Isolate both the hot and cold water supplies and disconnect the shower riser from the body.

Unscrew the 2 socket set screws and carefully pull the body from the inlets.

Carefully pull out the non return valves, flush out any debris and check for correct operation.

Remove the filters and flush thoroughly, remove any debris collected infront of the filter from the inlets.

Replace non return valves and filters if damaged with new.

Re-assemble in the reverse order turn on both supplies and check joints for leakage.

Aftercare

Inta thermostatic shower valves have a high quality finish and should be treated with care.

An occasional wipe with a mild washing-up liquid on a soft damp cloth followed by a thorough rinsing is

all that is required.

Do not use an abrasive or chemical household cleaner as this may cause damage.

IMPORTANT

IMPORTANT

The following information is required when the thermostatic shower valve is used in a TMV2

Applications under the requirements of BS EN 1111: 1999 “Sanitary tapware – Thermostatic

Mixing Valve (PN 10) – General Technical Specification”.

Supply Conditions

The supply conditions to the Thermostatic Mixing Shower Valve must comply with the following;

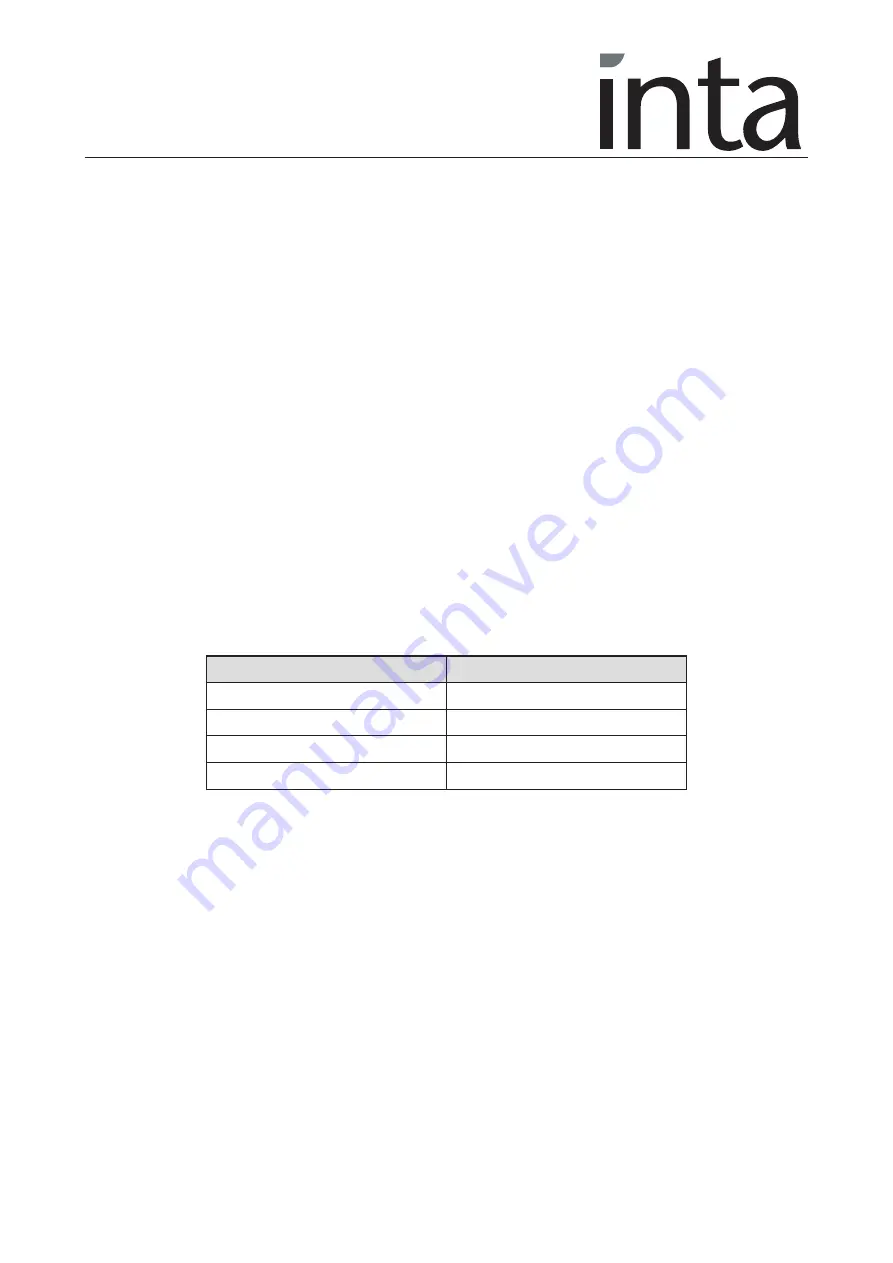

Conditions

High Pressure

Maximum Static Pressure

bar

10

Flow Pressure, Hot & Cold

bar

0.5 to 5

Hot Supply Temperature

˚C

55 to 65

Cold Supply Temperature

˚C

≤ 25˚C

Note: Valves operating outside these conditions cannot be guaranteed by the Scheme to operate as type

2 valves.

• The valves designation of use, HP if tested against BS EN 1111.

• For valves designated for use HP only, if a water supply is fed by gravity then the supply pressures

should be verified to ensure the conditions of use are appropriate for the valve.

Introduction

The thermostatic shower valve has been specifically designed and manufactured to meet the

requirements of BS EN 1111:1999 and TMV2 Type Scheme. The valve has been independently

tested and approved as a TYPE 2 valve under the BuildCert TMV2 scheme by the WRc Testing &

Evaluation Center.