© Intatec Ltd 2020

1

Introduction

This installation guide has been produced for the IR500CP & IR501CP infra red basin taps.

These instructions cover the installation, operation and maintenance. Please read the enclosed

instructions before commencing the installation of this product, please note;

We recommend that the installation of any Inta product is carried out by an

approved installer.

Products

Infra red basin mounted tap with battery box IR500CP

Infra red basin mounted tap with electronic transformer IR501CP

Check Contents

Before commencing remove all components from packaging and check each component with

the contents list.

Ensure all parts are present, before discarding any packaging. If any parts are missing, do not

attempt to install your Inta electronic tap until the missing parts have been obtained

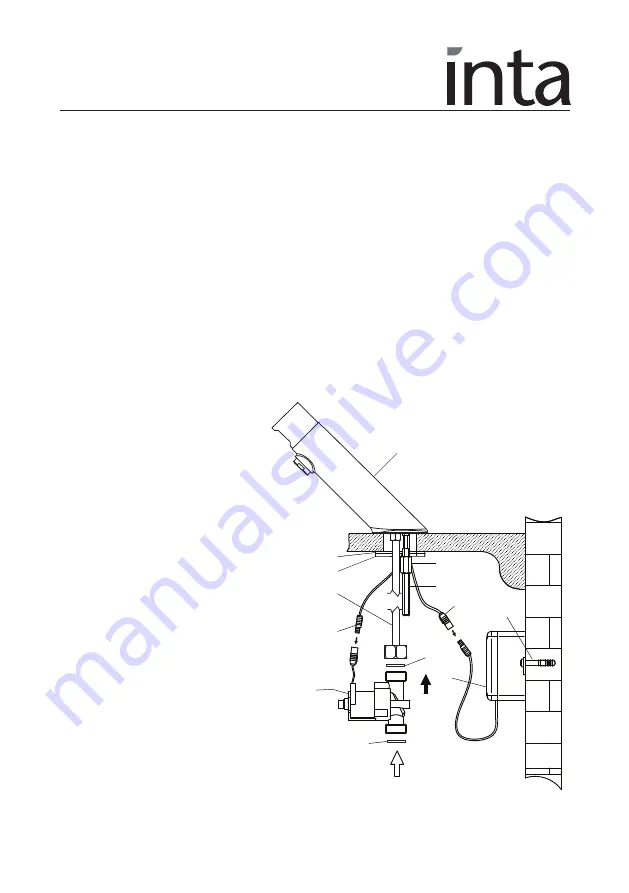

Item Qty Components

1

1

Tap with infra red sensor

2 1 Horse shoe sealing washer

3 1 Horse shoe metal washer

4 2 Securing nut

5 2 Threaded rod

6 1 Copper tail

7 1 Solenoid valve

8 1 Filter sealing washer

9 1 Sealing washer

10 1 Tap to valve (7) connector

11 1 Tap to electrical supply

connector

12 1 Battery holder or

transformer

13 2 Screws & wall plugs

Water

su

pp

ly

1

2

12

13

8

3

7

9

10

11

6

4

5