© Intatec Ltd 2022

12

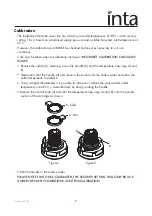

Maintenance

6.4 If significant changes (e.g. > 2˚K) in the mixed water temperature are recorded in both

of these periods necessitating service work, then the next in service test should be

carried out at 18 to 21 weeks after commissioning.

7 The general principle to be observed after the first 2 or 3 in-service tests is that the intervals

for future tests should be set to those which previous tests have shown can be achieved with

no more than a small change in mixed water temperature.

8 In all areas periodic maintenance of the valve and associated fittings i.e. strainers, check

valves will ensure optimum performance levels are maintained.

Spares

A full range of spares are available for this product from Inta.

PLEASE NOTE:

Only genuine spares should be used.

Summary of Contents for IT1007CP

Page 14: ...Intatec Ltd 2022 13 Notes...

Page 15: ...Intatec Ltd 2022 14 Notes...