© Intatec Ltd 2017

10

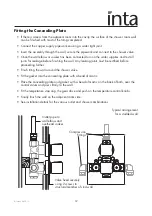

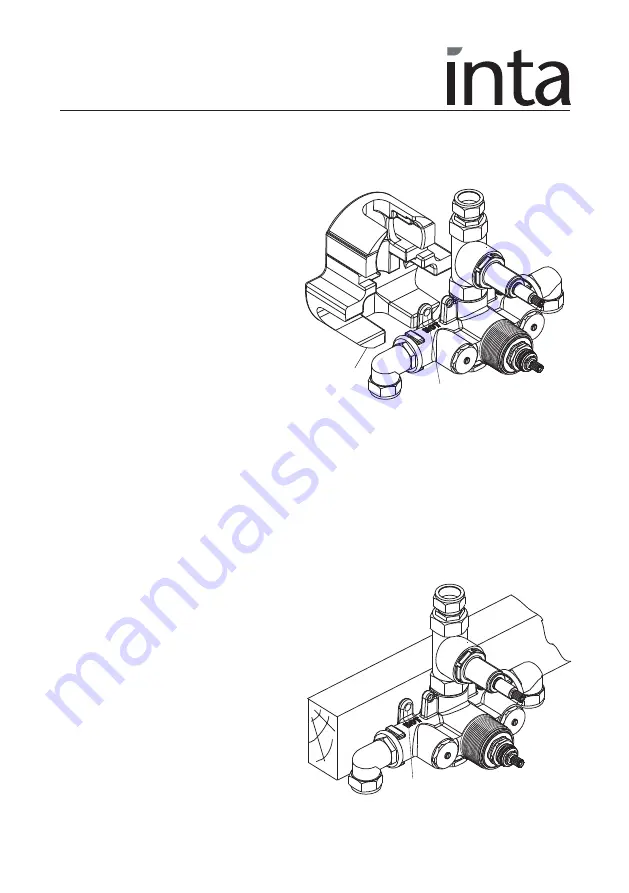

Solid wall

• Create a large enough cavity for the shower valve and chase the wall for the two supply

pipes and a route from the outlet of the shower valve to the outlet elbow and overhead

shower.

• If the shower valve is to be fitted in an

outside wall or where there is a

greater risk of freezing the preformed

insulation (17) should be used, which

will require a deeper cavity.

• If the preformed insulation is not used,

fix the shower valve into the cavity

using the 2 fixing holes ensuring the

valve is vertically in line.

• Ensure the thermostatic cartridge and

flow control valve protrude sufficiently

from the finished wall surface to allow

the concealing plate and control knobs

to be fitted, see dimension drawing.

Cavity wall

• The shower valve must be fixed securely to the structural members of the stud wall and/or an

additional member may need to be included where the shower valve will be located.

• If there is access from the adjacent room into the cavity, the surface of the shower room wall

can be finished with most of the tiling completed.

• Fix the shower valve to the structural member using 2 screws of sufficient length and tighten

to hold secure.

• Ensure the thermostatic cartridge and

flow control valve protrude sufficiently

from the finished wall surface to allow

the concealing plate and control knobs

to be fitted, see dimension drawing for

protrusion distance.

• Additional holes need to be made for the

outlet elbow and soaker arm. The tiling

around these holes needs to be

completed to allow the these components

to be fitted.

Fixing hole

Insulation

Fixing hole