© Intatec Ltd 2017

7

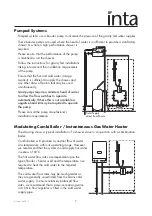

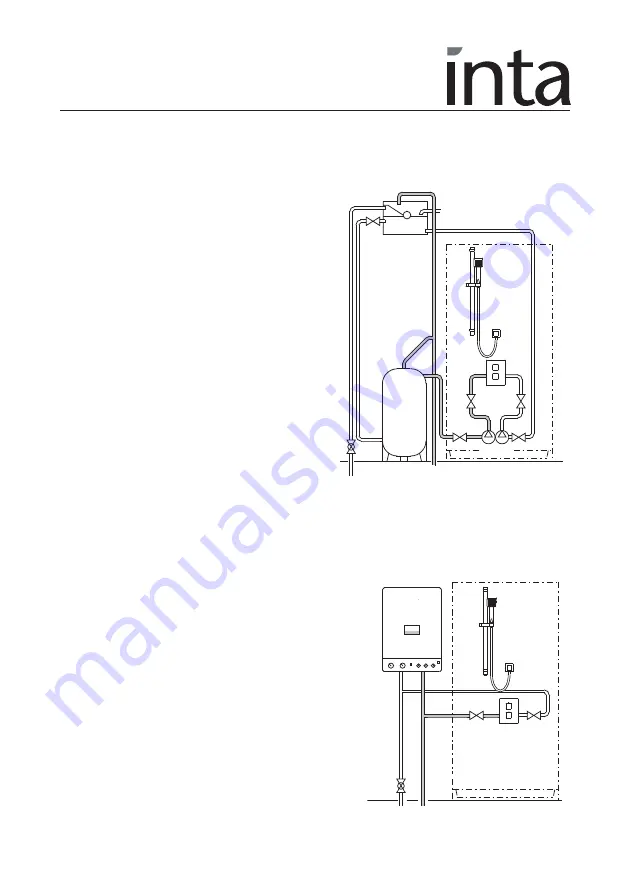

Pumped Systems

Pumped systems use a booster pump to increase the pressure of the gravity fed water supplies.

These booster pumps are used where the head of water is insufficient to provide a satisfactory

shower or where a high performance shower is

required.

Please ensure that the performance of the pump

is matched to suit the shower.

Follow the instructions for gravity fed installations

taking into account the installation requirements

of the pump.

Ensure that the hot and cold water storage

capacity is sufficient to supply the shower and

any other draw off points that may be used

simultaneously.

Most pumps require a minimum head of water

to allow the flow switches to operate

automatically. Where this is not available a

negative head kit may be required to operate

the pump.

Please consult the pump manufacturer’s

installation requirements

Modulating Combi Boiler / Instantaneous Gas Water Heater

The drawing shows a typical installation of a shower valve in conjunction with a combination

boiler.

Combi boilers will produce a constant flow of water

at a temperature within its operating range. However

we recommend that the system should supply hot water

in excess of 60˚C.

The hot water flow rates are dependant upon the

type of boiler / heater used and the temperature rise

required to heat the cold water to the required

temperature.

The cold water flow rates may be much greater as

they are generally unrestricted from the mains cold

water supply. To ensure relatively balanced flow

rates, we recommend that a pressure reducing valve

or 6 l/min flow regulator is fitted in the cold water

supply pipe.

Cold Supply

direct from Mains

Pumps