© Intatec Ltd 2017

3

Unvented Mains Pressure System

The drawing shows a typical installation of a

shower mixing valve in conjunction with an

unvented hot water system. This type of

installation must be carried out in accordance

with Part G of the Building Regulations.

Whilst pressures are theoretically equal

(balanced) most unvented hot systems have a

pressure reducing valve on the incoming cold

water prior to the hot water storage vessel.

This means that the hot and cold pressures can

be significantly different.

Most unvented systems use an inlet manifold

located directly after the pressure reducing

valve.

It is recommended that the cold supply be taken

from one of the outlets of the manifold directly to the shower as an independent supply.

For systems without a manifold unit after the pressure reducing valve and where the cold water

supply pressure is significantly higher than the hot supply we recommend that a separate

pressure reducing valve is fitted to the cold supply, as close as possible to the shower valve

and with no draw off points between it and the shower valve.

Flow regulators are required for installations where a PRV is not fitted to ensure simultaneous

demand is accounted for.

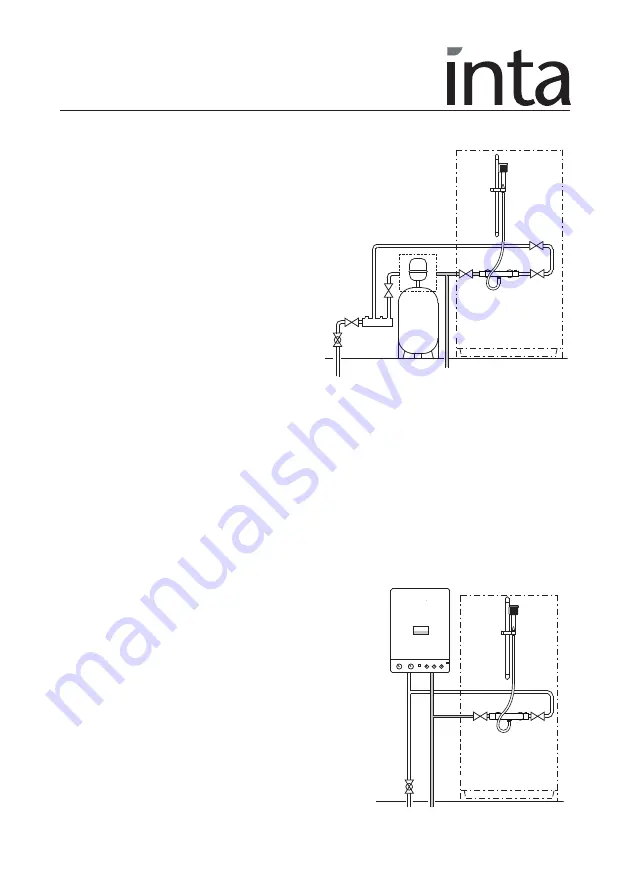

Modulating Combi Boiler / Instantaneous Gas Water Heater

The drawing shows a typical installation of a shower valve in conjunction with a combination

boiler.

Combi boilers will produce a constant flow of water at a

temperature within its operating range.

The hot water flow rates are dependant upon the type of

boiler / heater used and the temperature rise required

to heat the cold water to the required temperature.

The cold water flow rates may be much greater as

they are generally unrestricted from the mains cold

water supply. To ensure relatively balanced flow

rates, we recommend that a pressure reducing valve

or 6 l/min flow regulator is fitted in the cold water

supply pipe.

Manifold

PRV

PRV if

manifold is

not used

Cold Supply direct

from mains

Summary of Contents for Nulo CB10031CP

Page 19: ...Intatec Ltd 2017 18 Notes...