© Intatec Ltd 2017

16

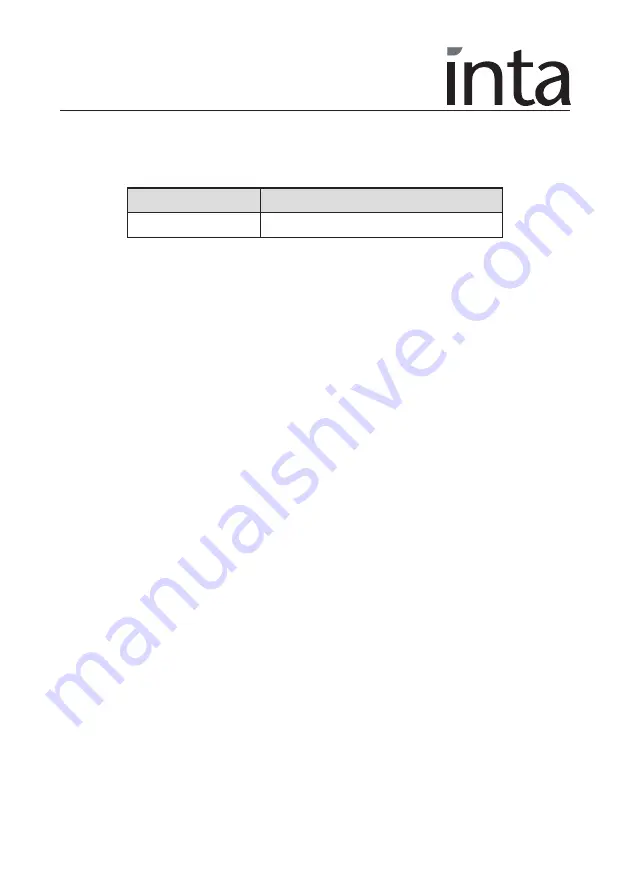

Recommended Outlet temperatures

The BuildCert TMV scheme recommends the following set maximum mixed water outlet

temperature for use in all premises:

The mixed water temperature must never exceed 43˚C.

The maximum mixed water temperature can be 2˚C above the recommended maximum set

outlet temperature.

Note:

43˚C is the maximum mixed water temperature from a shower mixer. The maximum

temperature takes account of the allowable tolerances inherent in thermostatic shower

mixers and temperature losses.

It is not a safe bathing Temperature for adults or children

.

The British Burns Association recommends 37 to 37.5˚C as a comfortable bathing

temperature for children. In premises covered by the Care Standard Act 2000, the

maximum mixed water outlet temperature is 43˚C.

Installation

Important

: - The following instructions must be read prior to the installation of the

thermostatic shower valve. The installer of the thermostatic shower valve must comply with the

requirements of the Water supply (Water Fittings) Regulations 1999 and also be aware of their

responsibility and duty of care to ensure that all aspects of the installation comply with the

regulations.

It has been brought to our attention that flushing water systems using certain chemicals may

wholly or partially remove the lubricant from the internal workings of the valve, which may

adversely affect its performance. We recommend that following flushing the system with

chemicals; valves are checked for correct operation.

1. It is essential that before installing any thermostatic shower valve to ensure that the supply

conditions of the system to which the valve is intended to be fitted are checked to confirm

compliance with the parameters as quoted within the technical specification and conditions

on which the approval is granted i.e. verify supply temperatures, supply pressures, risk

assessment.

2. Consideration must be made for the possibility of multiple / simultaneous demands being

made on the supply system whilst the thermostatic shower valve is in use, all practical

precautions must be made to ensure that the valve is not affected. Failure to make provision

within the pipe sizing etc. will affect the performance of the shower valve.

Application

Recommended Hot Water Temperature

Shower

41˚C

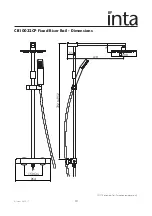

Summary of Contents for Nulo CB10032CP

Page 21: ...Intatec Ltd 2017 20 Notes...

Page 22: ...Intatec Ltd 2017 21 Notes...

Page 23: ...Intatec Ltd 2017 22 Notes...