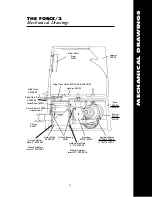

THE FORCE/2

Maintenance

Reasonable preventive maintenance will help ensure your FORCE/2 gives you

many years of satisfactory use. Cleaning the interior and exterior of your machine

and protecting its finish with a product such as Armor All will keep it looking new.

CORDS AND SWITCHES

The remote cord and switches are subject to considerable wear and tear during

normal use. Inspect all cords and switches each week for cuts or loose connections.

Repair or replace any damaged components at once to avoid possible injury.

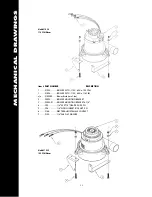

AIRLOCK BLOW BACK

Airlock seals are the most important component of keeping your FORCE/2

running in original condition. Airlock seals function much like the rings in a car

engine, keeping pressure and air from escaping. When a seal or plate is damaged,

air from the blower will escape back into the hopper causing “blow back.” Blow

back will result in a considerable decrease in production.

Checking for blow back; unplug the machine from electrical power and empty all

insulation material from the hopper. Block the hose outlet with duct tape, or use

the palm of your hand. Reconnect the power and

turn on both the blower and agitator motor. A hissing or puffing sound of air

escaping into the hopper indicates blow back.

In addition, any insulation material remaining

in the airlock will blow back into the hopper,

creating dust. To remedy blow back, it is

necessary to replace the airlock seals or plates.

Note:

Your FORCE/2 comes from the factory

preset to produce 3.2-4.8 PSI. You may purchase

a pressure gauge from Intec to aid in determining

the pressure developed by the blower and airlock, system.

M

A

I

N

T

E

N

A

N

C

E

19

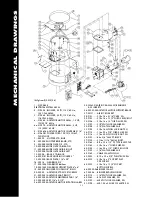

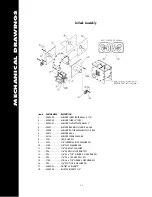

Summary of Contents for FORCE/2 HP

Page 2: ......

Page 4: ...MACHINE INFORMATION 2 ...

Page 46: ...ELECTRICAL DRAWINGS 44 Wiring Diagram Manufactured from 8 02 Present Electrical with GFCI ...

Page 49: ...ELECTRICAL DRAWINGS 47 Wiring Diagram Mfg from 9 02 Present Electrical With Remote Disconnect ...

Page 50: ......

Page 52: ...ELECTRICAL DRAWINGS FORCE 2 Electrical Drawings Cont d ...