O

P

E

R

A

T

I

N

G

W

I

T

H

A

G

E

N

E

R

A

T

O

R

/

U

S

I

N

G

A

D

D

I

T

I

O

N

A

L

E

X

T

E

N

S

I

O

N

C

O

R

D

S

17

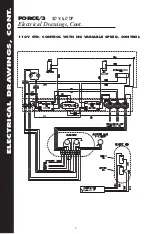

FORCE/3

3.0 & 4.0 DP

Operating With a Generator /

Using Additional Extension Cords

USING A GENERATOR:

Both the Force/3 3.0 & 4.0 DP operate best when using a use a

commercial sized generator. The start up requirement for both Force/3

machines is 10.5KW. Normal running wattage for the Force/3 3.0 is

4025 watts and the 4.0 DP is 4680 Watts. We recommend using a

minimum wattage of 10.5KW. While many brand name generators

(Honda, Generac, Yamaha, Coleman) are of high quality, they are not

commercial grade and are not built to handle the

high in-rush current

that is needed to start the agitator motor.

Consult Intec for further information or your local generator reseller.

Using a generator of insufficient size will cause internal motor damage

and will void machine warranty.

FORCE/3 MOTOR SPECIFICATIONS:

Blower 5.7 diameter

10.2 Amps @ 115 Volt x 2 blowers = 20.4 Amps

Blower 7.2 diameter

13.0 Amps @ 115 volt x 2 blowers = 26 Amps

GE

(model C371)

14.7 Amps @ 115 Volt

Leeson

(model 110420.00)

17.2 Amps @ 115 Volt

ADDITIONAL EXTENSION CORDS:

The FORCE/3 is supplied with the correct size power cords to deliver

the proper voltage to the motors. If you require additional extension

cords please follow the table on page 18. A smaller sized extension

cord is not advised and will lead to electrical or motor failure.

O

P

E

R

A

T

I

N

G

W

I

T

H

A

G

E

N

E

R

A

T

O

R

/

U

S

I

N

G

A

D

D

I

T

I

O

N

A

L

E

X

T

E

N

S

I

O

N

C

O

R

D

S