EMI and Mechanical Design Considerations

158

Design Guide

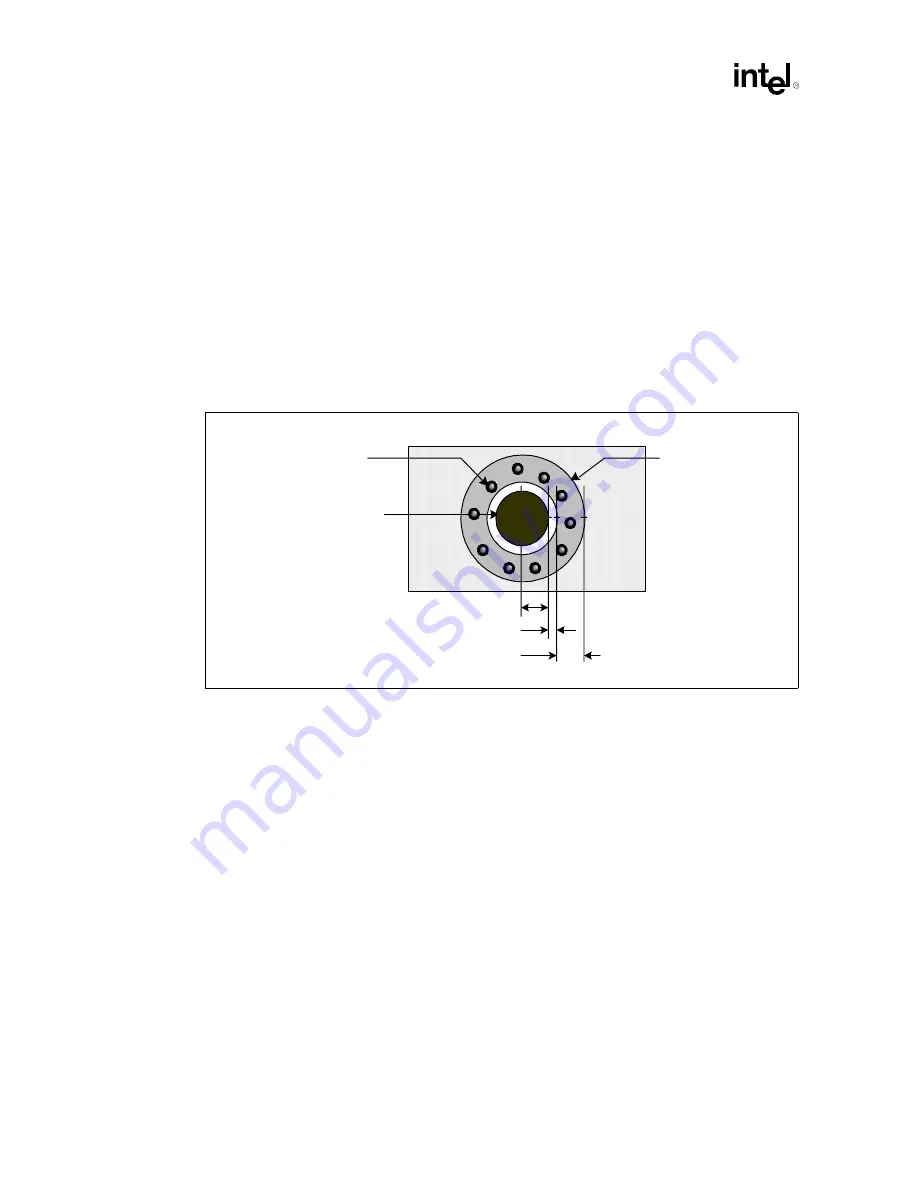

Utilization of the DC grounding strips requires ground pads around the mounting holes for the

retention mechanism. Metal inserts will be pre-assembled to the retention modules to establish DC

contact between heatsink base plate and the motherboard ground. The inserts will be grounded to

the baseboard at mounting hole ground pads. Fingers on top of the insert will connect to the base of

the heatsink. The requirements for the DC grounding insert are as follows:

•

All four RM mounting holes must have ground pad rings.

•

Ground pad annular ring should be no less than 125 mils wide. Try to cover the entire keep-out

zone, if possible. See

for better dimensions.

•

Place 8–12 vias in the annular ring, which connects the pad to internal ground planes.

•

Anodizing or any form of insulated coating of the heat sink is strongly discouraged.

for specific details regarding the required ground pads.

Figure 11-8. Retention Mechanism Ground Ring

80 mils

15 mils

125 mils

RM Mounting Hole

Ground Ring

VIA

Summary of Contents for Xeon

Page 24: ...Introduction 24 Design Guide This page is intentionally left blank ...

Page 30: ...Component Quadrant Layout 30 Design Guide This page is intentionally left blank ...

Page 52: ...Platform Clock Routing Guidelines 52 Design Guide This page is intentionally left blank ...

Page 66: ...System Bus Routing Guidelines 66 Design Guide This page is intentionally left blank ...

Page 118: ...Intel 82870P2 P64H2 118 Design Guide This page is intentionally left blank ...

Page 146: ...I O Controller Hub 146 Design Guide This page is intentionally left blank ...

Page 148: ...Debug Port 148 Design Guide This page is intentionally left blank ...

Page 210: ...Schematic Checklist 210 Design Guide This page is intentionally left blank ...

Page 220: ...Layout Checklist 220 Design Guide This page is intentionally left blank ...

Page 222: ...Schematics 222 Design Guide This page is intentionally left blank ...