13

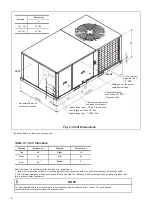

CAUTION

Label all wire prior to disconnection when servicing controls. Wiring errors

can cause improper and dangerous operation. Verify proper operation after

servicing.

CONTACTOR

GROUND

LUG

Refer to electrical data tables

to size the disconnect

Field-supplied disconnect

Single

p h a s e

p o w e r

supply

Fig. 6-2 Typical Field Power Wiring Diagram

R

G

Y

W

C

R

G

Y

W

1

W

2

C

24 volt

transformer

THERMOSTAT

UNIT CONTROL BOARD

THERMINAL STRIP

*** B wire be used with heat pump system only.

** Minimum wire size of 18 AWG wire should be used for all field installed

24 volt wire.

* Only required on units with supplemental electric heat.

Fig. 6-1 Typical Field Control Wiring Diagram

B

B

240V

208V

COM

***

*

**