GA-160 Operation & Maintenance Manual

Page 3 of 8

1.0 INSTALLATION

1.1

MOUNTING:

The amplifier comes standard with a foot mounting bracket (four 1/4 inch fasteners required).

The unit may be mounted vertically (wall mount) or horizontally (floor mount).

1.2

CONNECTIONS:

Connect a regulated and filtered air supply to the 1/2 NPT "AIR IN" port on the pump (1/2 NPT, or

larger size filter/regulator and plumbing. NO Lubricator Is required).

Connect your source media to be pumped to 1/2 NPT “GAS IN” Ports.

Connect your destination media circuit to the 1/2 NPT “OUT” Port located in the center section of the

pump.

1.3

STARTUP:

Note: With the source media supply turned on, it will free-flow through the pump to the destination

port, with a slight pressure drop due to the cracking pressure of the internal check valves.

Starting with the external air regulator backed-out all the way, slowly increase the pressure by turning

the regulator knob clockwise. The pump will start to cycle building pressure of destination media as it

does so.

The pump will stall when circuit pressure reaches the sum of the regulated drive pressure and the

inlet media pressure. The pump will maintain this pressure even if there is some circuit leakage. At

this time check for and fix any circuit leaks since this only causes unnecessary air consumption and

wear and tear on the pump.

2.0 MAINTAINENCE:

2.1 ROUTINE MAINTAINENCE:

The only routine maintenance required is to re-grease the main air spool (item 9), the pilot piston

O-ring (item 10) and the T-seals (items 7) every 6 months. Refer to the enclosed 4-way cycling valve

assembly drawing.

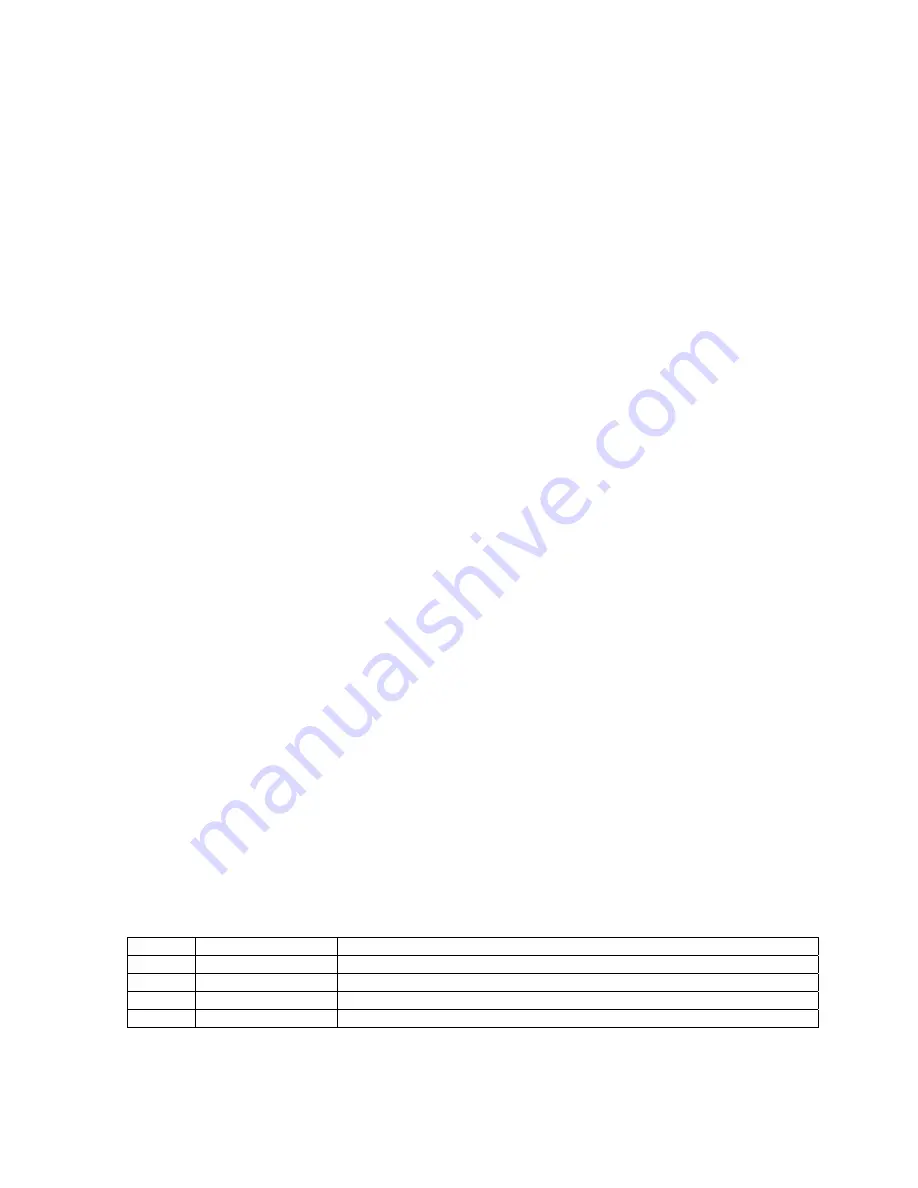

2.2 RECOMMENDED SPARE PARTS*

QTY PART

NUMBER

DESCRIPTION

1

12894

Kit, 4-Way Air Reciprocation Valve

1

11690

Kit, Seal (All Seals)

3

10017

2-Way Air Valve Assembly

*Consult your local distributor or IDI for current price and delivery.