Intermec EasyCoder 601 XP – Installation & Operation Ed. 3

94

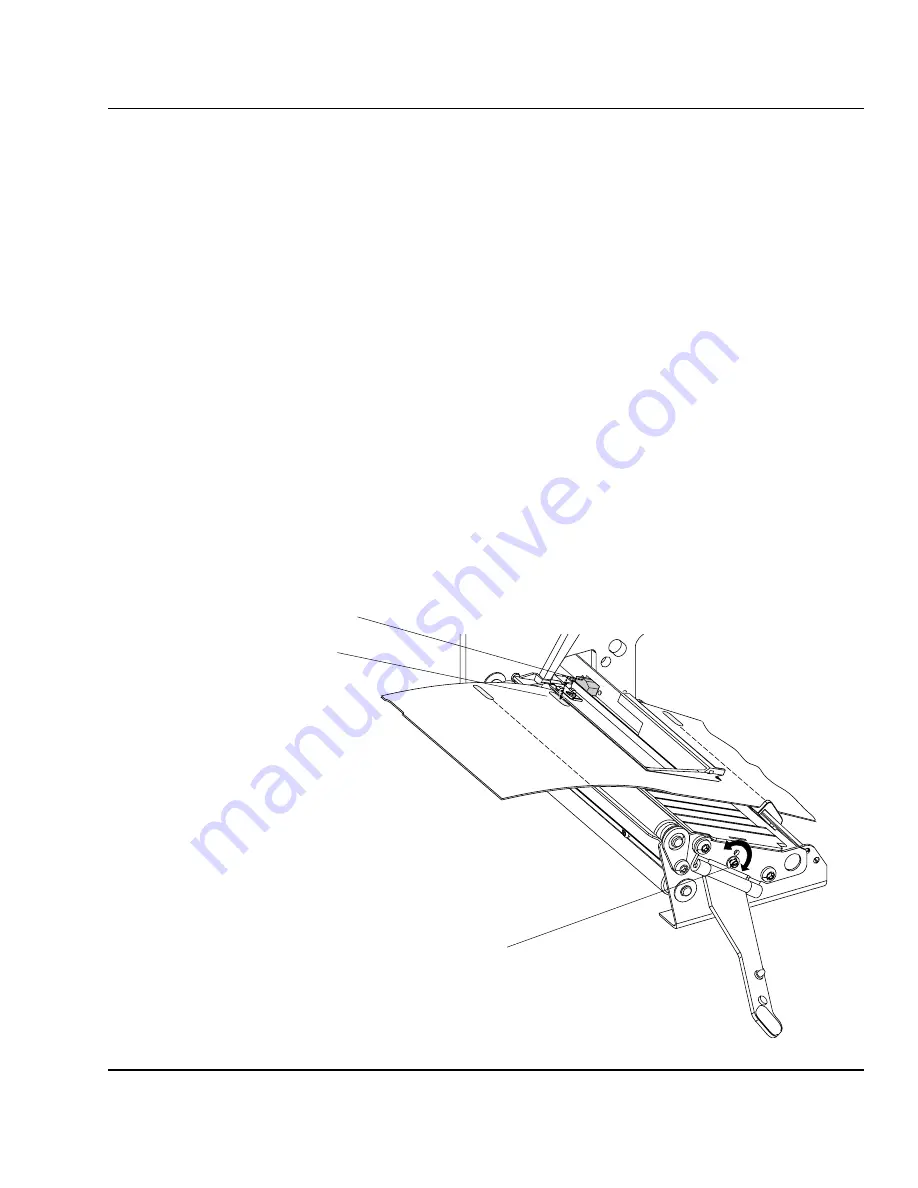

Chapter 13 Adjustments

OUT

IN

Label Stop Sensor

Position

The label stop sensor (LSS) is a photoelectric sensor that controls

the printer's paper feed by detecting gaps between labels, slots in

paper strip, or black marks, depending on the printer's setup in re-

gard of media type (see chapter 7 “Setting Up the Printer”). A pre-

requisite is obviously that the LSS is aligned with the slots or black

marks.

The label stop/black mark sensor (LSS) can be laterally adjusted

within a range of 0 to 50 mm (1.96") from the inner edge of the

paper by means of a screw accessible through the outer lower ga-

ble. Turning the screw clockwise will move the LSS inwards and

vice versa. The position of the LSS in relation to the paper is best

checked by looking head on into the print unit when the printhead

is lifted. Align the centrepoint of the V-shaped upper sensor with

the centre of the slots or marks to be detected.

The linear markings on the lower guide plate can also be used for

positioning of the LSS as they are spaced with an interval of exactly

1 cm (0.39") from the edge that guides the paper. This method is

especially useful for black marks (measure the lateral position of

the black marks with a ruler before loading the paper).

If using irregularly shaped labels, align the LSS with the front tips

of the labels

Upper part of print unit removed to improve view.

Upper part of LSS

Adjustment Screw

Detection Slot