Chapter 4 — Troubleshooting and Maintaining the Printer

PF2i and PF4i Mid-Range Printer User’s Manual

103

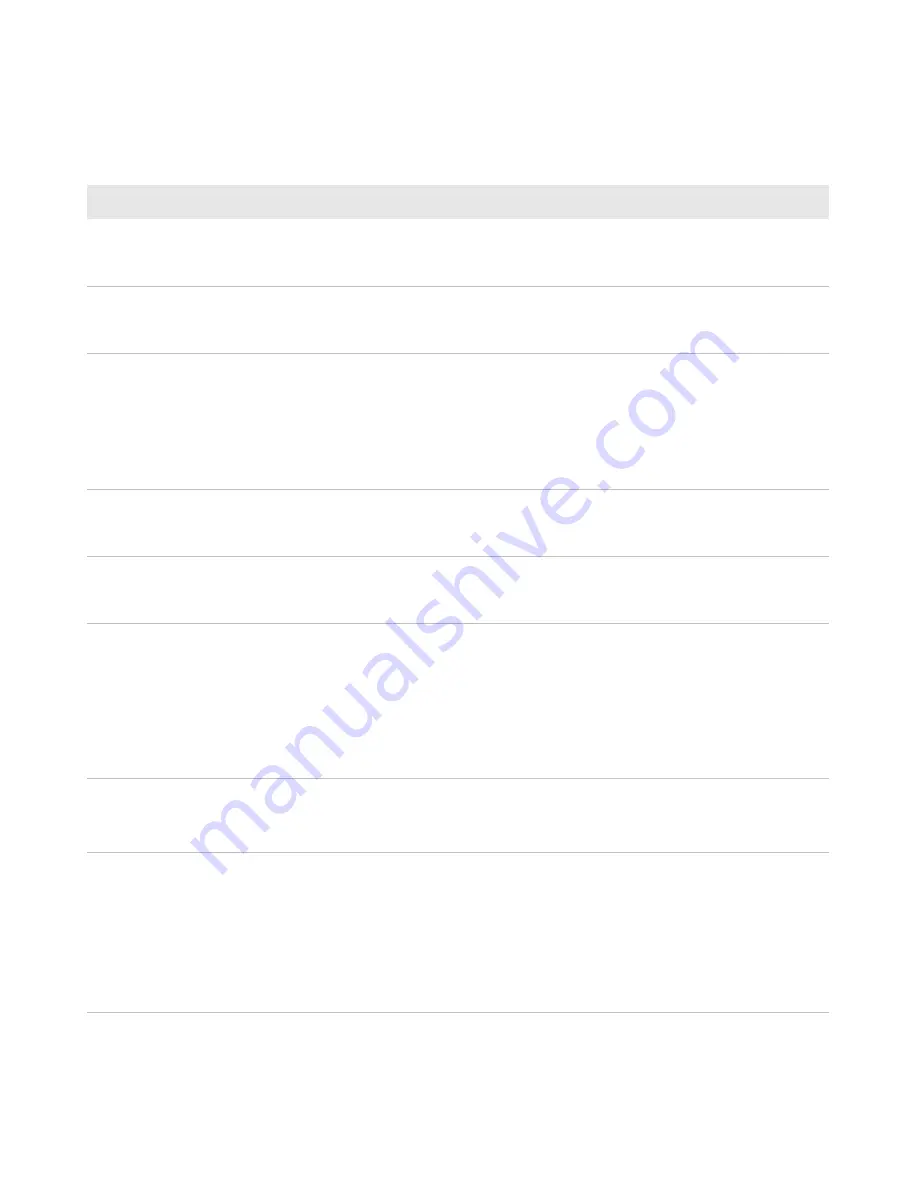

RFID Problems and Possible Solutions

Problem

Possible Solution

I loaded my printer with RFID

media, but it is not writing to the

tags.

After you load RFID media, restart the printer or run a

TESTFEED to let the printer identify the RFID media type.

The RFID kit is installed, but

“RFID” does not appear in the setup

tree.

The printer is not communicating properly with the RFID

hardware. For help, contact your local Intermec

representative.

When I try to set RFID MODE to

ENABLE, I get one of these error

messages:

•

“Error in filename” (Fingerprint

or Intermec Direct Protocol)

•

“No RFID support” (IPL)

An RFID kit is not installed in the printer. For help, contact

your local Intermec representative.

None of the RFID commands work,

and I get this message: “RFID

Inactive.”

RFID MODE is disabled. Change MODE to ENABLE.

Printing on regular media (not

RFID) is slow and halted in between

labels.

RFID MODE is enabled. Change MODE to DISABLE.

I am using an application to write to

RFID tags, and the printer is

printing “VOID” labels.

•

The printer may not recognize the RFID media type. For

Fingerprint printers, run a TESTFEED. For IPL printers,

raise and lower the printhead, and then press

F

or turn

on the printer.

•

You may need to modify the TAGADJUST parameter.

•

You may need to adjust the output power (field strength)

to the antenna.

When I try to perform a TESTFEED,

I get this message, “No tag found.”

•

Make sure that you are using RFID media.

•

You may need to modify the TAGADJUST parameter.

•

The tag may be broken. Try printing on a different label.

I get this error message: “Not

supported by tag type.”

(Fingerprint)

This error message indicates that a command:

•

may be trying to access a tag data segment that is not

available on the RFID media.

•

is being used with a level of security that is not allowed by

the tag type.

Make sure that you are using the appropriate media for

your application.

Summary of Contents for EasyCoder PF2i

Page 1: ...PF2i PF4i Mid Range Printer User s Manual ...

Page 9: ...Contents PF2i and PF4i Mid Range Printer User s Manual ix I Index 171 ...

Page 10: ...Contents x PF2i and PF4i Mid Range Printer User s Manual ...

Page 14: ...Before You Begin xiv PF2i and PF4i Mid Range Printer User s Manual ...

Page 74: ...Chapter 2 Connecting the Printer 60 PF2i and PF4i Mid Range Printer User s Manual ...

Page 161: ...147 B Default Settings ...

Page 168: ...Appendix B Default Settings 154 PF2i and PF4i Mid Range Printer User s Manual ...

Page 185: ...171 I Index ...

Page 193: ......