IV7 Vehicle-Mount Reader Instructions

9

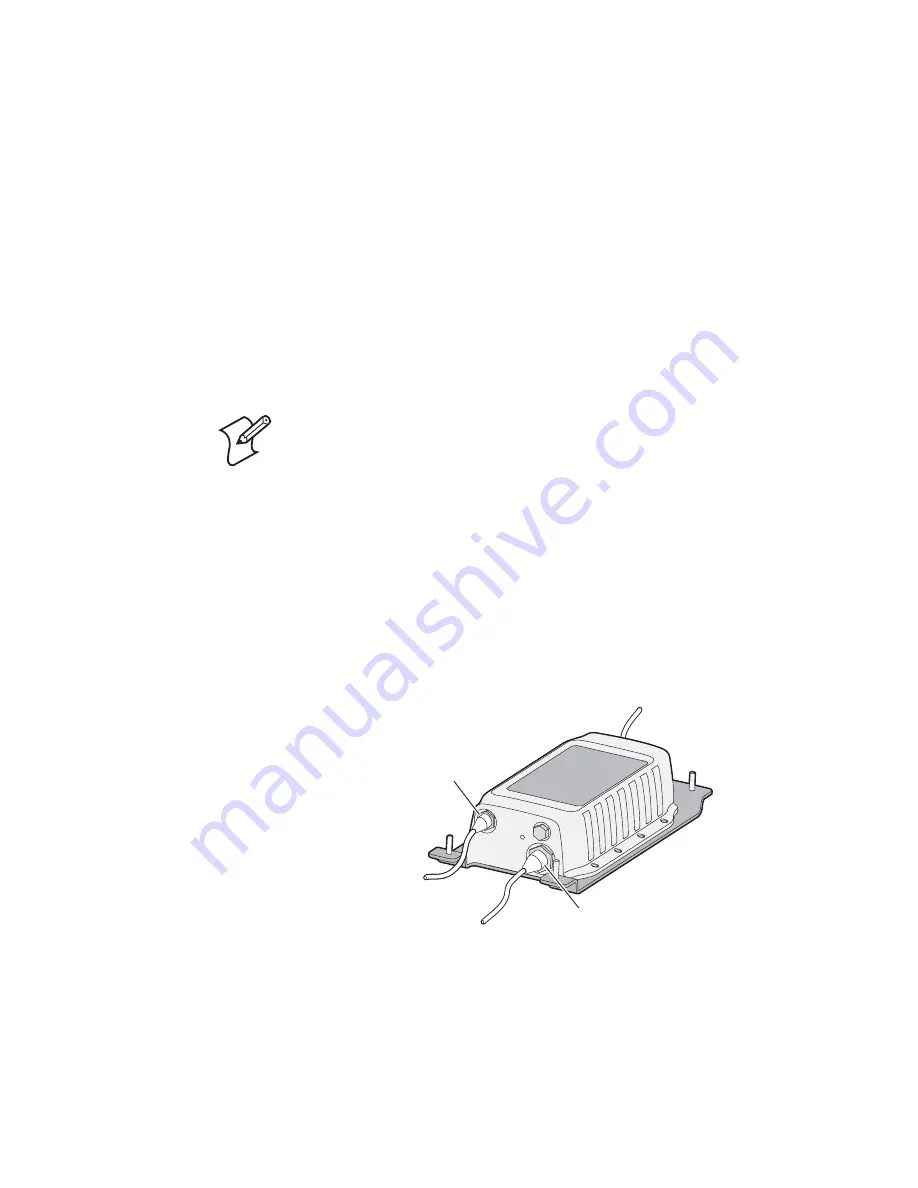

Installing the IV7

Before you install the IV7, antenna, or cables:

• the adaptable load back rest should be installed on the forklift

by a qualified technician.

• determine where the IV7 and antennas should be mounted

on the adaptable load back rest. For mounting location

guidelines, see page 6.

• determine where the IV7 power, data, and antenna cables

should be routed, and prepare the cables for installation. For

cable routing guidelines, see page 8.

To install the IV7 on the load back rest

1

Unscrew the four 5/16"-18 locknuts from the IV7 and

remove the mounting brackets.

2

Connect the power, data, and antenna cables to the IV7. Do

not connect the cables to any other component.

3

Position the IV7 in its mounting location on the back side of

the load back rest. The IV7 label should face forward.

4

From the front of the load back rest, slide the mounting

brackets onto the bolts on the IV7 baseplate.

Note:

The IV7 requires 6-60 VDC at up to 4.5A for

operation. Consult the vehicle manufacturer or your vehicle

maintenance company for specific information on appropriate

power connection and mounting locations.

To 6-60 VDC

To PC serial port

and GPIO devices

Power port

Data port

To RFID antenna

(up to 4)