421 01 5001 00

March 2008

INSTALLATION INSTRUCTIONS

R-22 Split System Air Conditioner

Product Family: N2A3, C2A3, H2A3, T2A3, N2A4

These instructions must be read and understood completely before attempting installation.

DANGER, WARNING, CAUTION, and

NOTE

The signal words

DANGER, WARNING,

CAUTION,

and

NOTE

are used to identify levels of

hazard seriousness. The signal word

DANGER

is

only used on product labels to signify an immediate

hazard. The signal words

WARNING,

CAUTION,

and

NOTE

will be used on product labels and

throughout this manual and other manuals that may

apply to the product.

DANGER

- Immediate hazards which

will

result in

severe personal injury or death.

WARNING

- Hazards or unsafe practices which

could

result in severe personal injury or death.

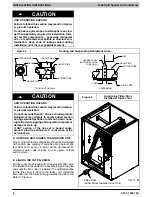

CAUTION

- Hazards or unsafe practices which

may

result in minor personal injury or product or

property damage.

NOTE

- Used to highlight suggestions which

will

result in enhanced installation, reliability, or operation.

Signal Words in Manuals

The signal word

WARNING

is used throughout this

manual in the following manner:

The signal word

CAUTION

is used throughout this

manual in the following manner:

Signal Words on Product Labeling

Signal words are used in combination with colors

and/or pictures on product labels.

WARNING

Safety Labeling and Signal Words

!

CAUTION

WARNING

!

TABLE OF CONTENTS

Inspect New Unit

2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Considerations

2

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Location

2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clearances

2 - 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unit Support

4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Refrigeration System

5 - 8

. . . . . . . . . . . . . . . . . . . . . . . .

Electrical Wiring

9 - 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start-up Procedure

11

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Refrigerant Charge

11

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sequence of Operation

11

. . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting

12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance

12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Comfort Alert

t

Diagnostics Codes

13

. . . . . . . . . . . . . .

!

WARNING

DEATH, PERSONAL INJURY, AND/OR PROPERTY

DAMAGE HAZARD

Failure to carefully read and follow this warning

could result in equipment malfunction, property

damage, personal injury and/or death.

Installation or repairs made by unqualified per‐

sons could result in equipment malfunction, prop‐

erty damage, personal injury and/or death.

The information contained in this manual is in‐

tended for use by a qualified service technician fa‐

miliar with safety procedures and equipped with

the proper tools and test instruments.

Installation must conform with local building

codes and with the National Electrical Code

NFPA70 current edition or Canadian Electrical

Code Part 1 CSA C.22.1.