13

440 01 1051 02

Specifications are subject to change without notice.

openings in doors or floors having a total minimum free area of

2 in.

2

/1,000 BTUH (44 cm

2

/kW) of total input rating of all

appliances.

•

An attic or crawl space may be considered a space that freely

communicates with the outdoors provided there are adequate

ventilation openings directly to outdoors. Openings

MUST

remain open and

NOT

have any means of being closed off.

Ventilation openings to outdoors

MUST

be at least 1 square

inch of free area per 4,000 BTUH (5.5cm

2

/kW) of total input

rating for all gas appliances in the space.

•

In spaces that use the

Indoor Combustion Air

Method,

infiltration should be adequate to provide air for combustion,

ventilation and dilution of flue gases. However, in buildings

with unusually tight construction, additional air

MUST

be

provided using the methods described in section titled

Outdoor Combustion Air

Method

:

•

Unusually tight construction is defined as Construction with:

1. Walls and ceilings exposed to the outdoors have a

continuous, sealed vapor barrier. Openings are gasketed

or sealed and

2. Doors and openable windows are weather stripped and

3. Other openings are caulked or sealed. These include

joints around window and door frames, between sole

plates and floors, between wall

−

ceiling joints, between

wall panels, at penetrations for plumbing, electrical and

gas lines, etc.

Ventilation Air

Some provincial codes and local municipalities require ventilation

or make

−

up air be brought into the conditioned space as

replacement air. Whichever method is used, the mixed return air

temperature across the heat exchanger

MUST

not fall below 60

°

so that flue gases will not condense excessively in the heat

exchanger. Excessive condensation will shorten the life of the heat

exchanger and possibly void your warranty.

Venting and Combustion Air Check

NOTE

: If this installation replaces an existing furnace from a

commonly vented system, the original venting system may no

longer be sized to properly vent the attached appliances. An

improperly sized venting system may cause the formation of

condensate in the vent and the leakage or spillage of vent gases.

To make sure there is adequate combustion air for all appliances,

MAKE THE FOLLOWING CHECK

.

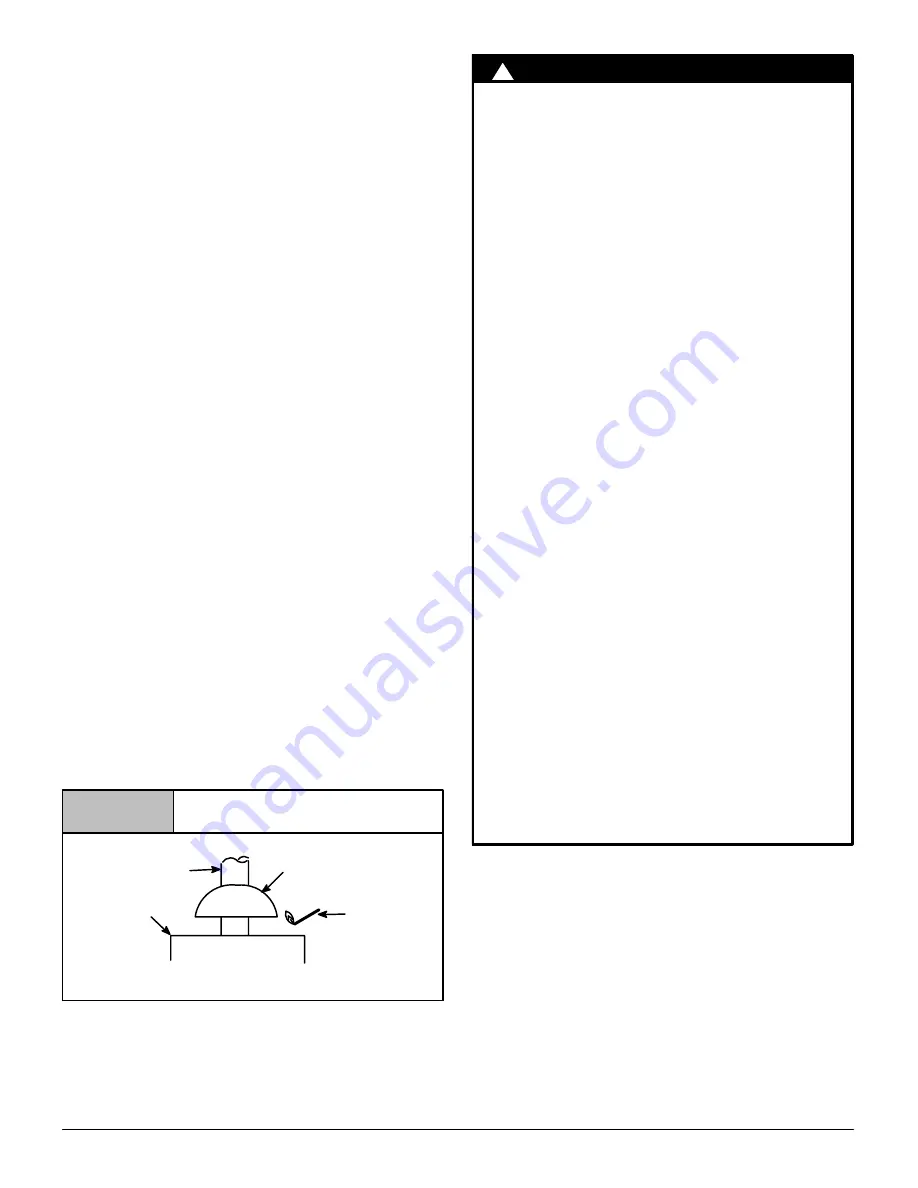

Vent Check

Draft Hood

Vent Pipe

Match

Typical Gas

Water Heater

Figure 7

If flame pulls towards draft hood, this indicates sufficient

venting.

The following information is supplied to allow the installer to make

adjustments to the setup of existing appliances,

IF REQUIRED,

based on good trade practices, local codes, and good judgement

of the installer. Manufacturer does

NOT

take responsibility for

modifications made to existing equipment.

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each

appliance connected to the venting system being

placed into operation, could result in carbon

monoxide poisoning or death:

The following steps shall be followed for each

appliance connected to the venting system being

placed into operation, while all other appliances

connected to the venting system are not in

operation:

1. Seal any unused openings in the venting system.

2. Inspect the venting system for proper size and horizontal

pitch, as required in the

National Fuel Gas Code, ANSI

Z223.1/NFPA 54

or

CSA B149.1, Natural Gas and

Propane Installation Code

and these instructions. Deter-

mine that there is no blockage or restriction, leakage,

corrosion and other deficiencies which could cause an

unsafe condition.

3. As far as practical, close all building doors and windows

and all doors between the space in which the appliance(s)

connected to the venting system are located and other

spaces of the building.

4. Close fireplace dampers.

5. Turn on clothes dryers and any appliance not connected

to the venting system. Turn on any exhaust fans, such as

range hoods and bathroom exhausts, so they are

operating at maximum speed. Do not operate a summer

exhaust fan.

6. Follow the lighting instructions. Place the appliance being

inspected into operation. Adjust the thermostat so

appliance is operating continuously.

7. Test for spillage from draft hood equipped appliances at

the draft hood relief opening after 5 minutes of main burner

operation. Use the flame of a match or candle. (

Figure 7

)

8. If improper venting is observed, during any of the above

tests, the venting system must be corrected in

accordance with the

National Fuel Gas Code, ANSI

Z223.1/NFPA 54

and/or

CSA B149.1, Natural Gas and

Propane Installation Code

.

9. After it has been determined that each appliance

connected to the venting system properly vents when

tested as outlined above, return doors, windows, exhaust

fans, fireplace dampers and any other gas

−

fired burning

appliance to their previous conditions of use.

!

WARNING

For Two Pipe Installation (Direct Vent)

This furnace can NOT be common vented or connected to any

type B, BW or L vent or vent connector, nor to any portion of a

factory

−

built or masonry chimney. If this furnace is replacing a

previously common-vented furnace, it may be necessary to resize

the existing vent and chimney to prevent oversizing problems for

the other remaining appliance(s). See

“Venting and Combustion

Air Check”

in this

section

.

This furnace MUST be vented to the

outside.