38

440 01 1051 02

Specifications are subject to change without notice.

3. For operation with Propane gas, gas orifices

MUST

be

changed and manifold pressure

MUST

be

maintained

as

per

Table 7.

Orifices can be ordered through our distributor.

(See Figure 39)

High Altitude Input Rate =

Nameplate Sea Level Input Rate x (Multiplier) *

{

Elevation

High Altitude Multiplier

Natural Gas

Propane Gas

2001

′

- 3000

′

{

(609.9

−

914.4)

{

0.95

0.90

3001

′

- 4000

′

(914.7

−

1219.2)

0.93

0.86

4001

′

- 5000

′

(1219.5

−

1524)

0.91

0.82

5001

′

- 6000

′

(1524.3

−

1828.8)

0.89

0.78

6001

′

- 7000

′

(1829.1

−

2133.6)

0.87

0.74

7001

′

- 8000

′

(2133.9

−

2438.4)

0.85

0.70

*

Based on mid

−

range of elevation.

High Altitude Air Pressure Switch

Altitudes over 4,000

′

(1219.2m) may require a different air

pressure switch than the one installed at the factory. Check parts

list for pressure switch and consult your distributor for part number

and availability. In Canada, provincial codes may govern

installation of switch. Check with governing authorities.

*

In the USA,

derating of these furnaces at 2% (Natural Gas)

and 4% (Propane Gas) has been tested and design

−

certified

by CSA.

{

In Canada

, the input rating must be derated 5% (Natural Gas)

and 10% (Propane Gas) for altitudes of 2,000 to 4,500 (609.6

to1371.6m) above sea level. Use the 2001 to 3000 (609.9 to

914.4m) column in

Table 6

and

Table 7

.

Changing Orifices for High Altitude

ELECTRICAL SHOCK, FIRE OR EXPLOSION

HAZARD

Failure to follow this warning could result in

personal injury, death, and/or property damage.

Turn OFF electric power at fuse box or service

panel and gas supply at manual valve in gas valve,

lockout and tag switch with a suitable warning

label, when installing orifices. Installation of

orifices requires a qualified service technician.

!

WARNING

NOTE:

Main burner orifices can be changed for high altitudes.

1. Disconnect gas line from gas valve.

2. Remove manifold from furnace.

3. Remove the orifices from the manifold and replace them

with properly sized orifices.

4. Tighten orifices so it is seated and gas tight.

(See

Figure 39

)

5. Reinstall manifold. Ensure burners do

NOT

bind on new

orifices.

Natural Gas Input Rating Check

SEE CHECKS AND ADJUSTMENTS, Natural Gas Input Rating

Check

in this manual.

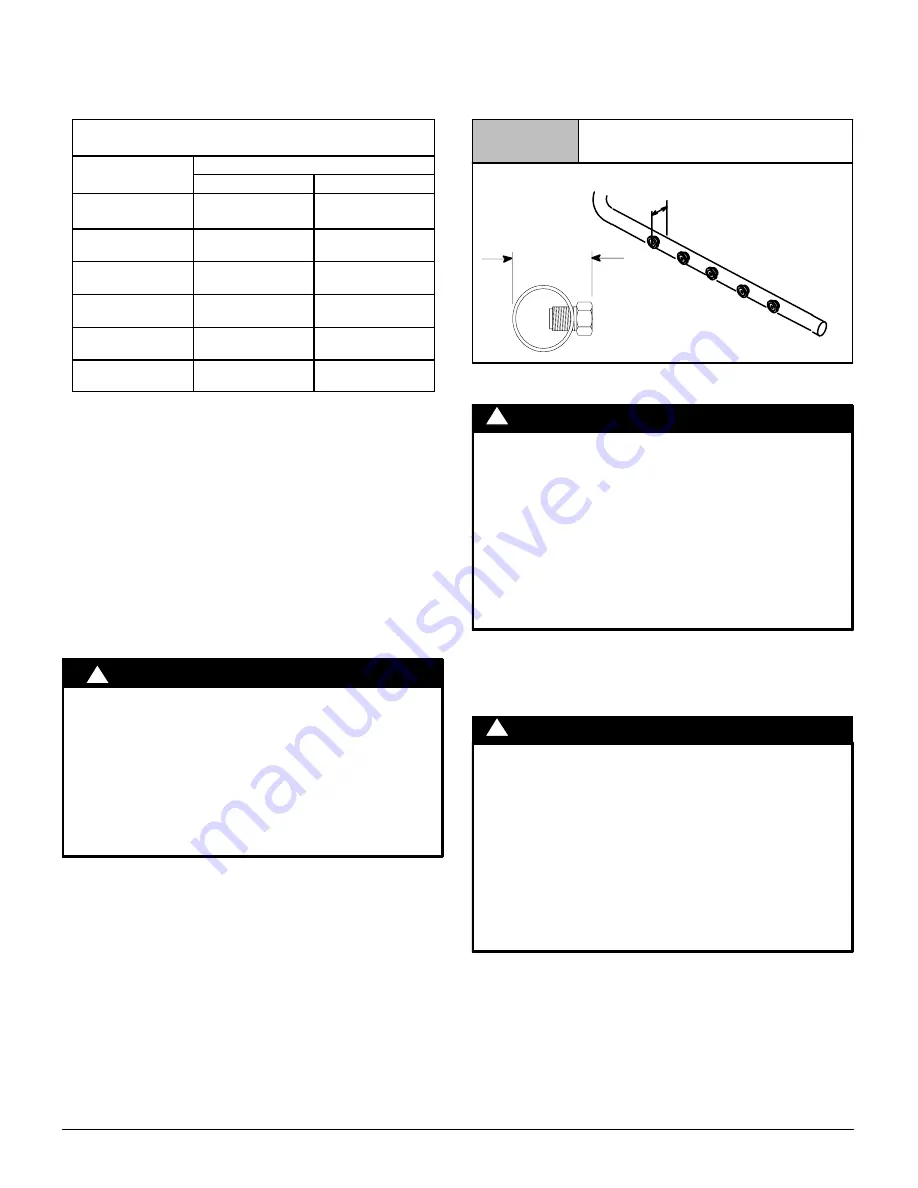

Figure 39

Changing Orifices

Measure from face of orifice

to the back side of the

manifold.

1.11

″

(28.2mm)

1.21

″

(30.8mm)

Final Gas Piping Check

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in

personal injury, death, and/or property damage.

Never test for gas leaks with an open flame. Use a

commercially available soap solution made

specifically for the detection of leaks to check all

connections. A fire or explosion could result

causing property damage, personal injury and/or

loss of life.

!

WARNING

1. The furnace and the equipment shut off valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess

of

1

/

2

″

PSIG. Close the manual shut

−

off valve before testing

at such pressures.

RISQUE D

‘

INDENDIE OU D

‘

EXPLOSION

Le non

−

respect des avertissements de sécurité

pourrait d

‘

entrainer des blessures graves, la mort

ou des dommages matériels.

Ne jamais utiliser une flamme nue por vérifier la

présence des fuites de gaz. Pour la vérification de

tous les joints, utiliser plutôt une solution

savonneuse commerciale fabriquée

spécifiquement pur la détection des fuites de gaz.

Un incendie ou une explosion peut entrainer des

dommages matériels, des blessures ou la mort.

!

AVERTISSEMENT

2. When installation is complete, test all pipe connections for

leaks with the gas pressure less than

1

/

2

″

PSIG to the gas

valve.

3. The furnace must be isolated from the gas supply system by

closing the equipment shut off valve during any pressure

testing of the gas supply system at test pressure equal to or

less than

1

/

2

″

PSI.

4. Apply a commercial soap solution to all joints to test for

leaks. Correct any leaks indicated by bubbles.

5. Correct even the smallest leak at once.

6. Check for leaks at gas valve and orifice connections to the

burner manifold while the furnace is operating.