Cooling Model Heat Pump

DFS2A324K1A DFS2H324K1A

DFS2A330K1A DFS2H330K1A

DFS2A336K1A DFS2H336K1A

DFS2A/H 24, 30, 36

Duct Free Systems

51302618914

−

D

Nov

06

421 01 9218 00

R

−

22

Installation, Start-Up, and Service Instructions

CONTENTS

Page

SAFETY CONSIDERATIONS

1

. . . . . . . . . . . . . . . . . . . . . .

GENERAL

1

−

6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

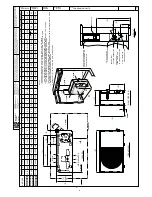

INSTALLATION 7

−

15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Indoor Unit Installation

7

. . . . . . . . . . . . . . . . . . . . . . . .

Outdoor Unit Installation

9

. . . . . . . . . . . . . . . . . . . . . . . .

Power Supply

10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Leak Test

10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Diagrams

12

−

13

. . . . . . . . . . . . . . . . . . . . . . . . . .

START

−

UP

14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Checks

14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CARE AND MAINTENANCE

14

. . . . . . . . . . . . . . . . . . . . . .

Outdoor Units

14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Indoor Units

14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

To Clean the Indoor Unit Front Panel

14

. . . . . . . . . . .

To Clean Indoor Coil

14

. . . . . . . . . . . . . . . . . . . . . . . . . .

Air Filters for Outdoor Units

14

. . . . . . . . . . . . . . . . . . .

INDOOR UNITS

14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE

15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING

16

−

19

. . . . . . . . . . . . . . . . . . . . . . . .

SAFETY CONSIDERATIONS

Installing, starting up, and servicing air

−

conditioning equipment

can be hazardous due to system pressures, electrical components,

and equipment location (roofs, elevated structures, etc.).

Only trained, qualified installers and service mechanics should

install, start

−

up, and service this equipment.

Untrained personnel can perform basic maintenance functions

such as cleaning coils. All other operations should be performed

by trained service personnel.

When working on the equipment, observe precautions in the

literature and on tags, stickers, and labels attached to the equipment.

Follow all safety codes. Wear safety glasses and work gloves.

Keep quenching cloth and fire extinguisher nearby when brazing.

Use care in handling, rigging, and setting bulky equipment.

DANGER, WARNING, CAUTION, and

NOTE

The signal words

DANGER, WARNING, CAUTION,

and

NOTE

are used to identify levels of hazard serious-

ness. The signal word

DANGER

is only used on

product labels to signify an immediate hazard. The

signal words

WARNING,

CAUTION,

and

NOTE

will

be used on product labels and throughout this manu-

al and other manuals that may apply to the product.

DANGER

−

Immediate hazards which

will

result in se-

vere personal injury or death.

WARNING

−

Hazards or unsafe practices which

could

result in severe personal injury or death.

CAUTION

−

Hazards or unsafe practices which

may

re-

sult in minor personal injury or product or property

damage.

NOTE

−

Used to highlight suggestions which

will

result in

enhanced installation, reliability, or operation.

Signal Words in Manuals

The signal word

WARNING

is used throughout this

manual in the following manner:

The signal word

CAUTION

is used throughout this

manual in the following manner:

Signal Words on Product Labeling

Signal words are used in combination with colors and/or

pictures on product labels.

WARNING

Safety Labeling and Signal Words

!

CAUTION

WARNING

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing or servicing system, always turn off main

power to system and install lockout tag on disconnect.

There may be more than one disconnect switch.

!

WARNING

GENERAL

These instructions cover the installation, start

−

up and servicing of

DFC2A/DFC2H

outdoor and

DFF2A/DFF2H

indoor units

cooling only and heat pump duct free systems. See Table 1 for

parts included. See Tables 2 and 3 for Physical Data.